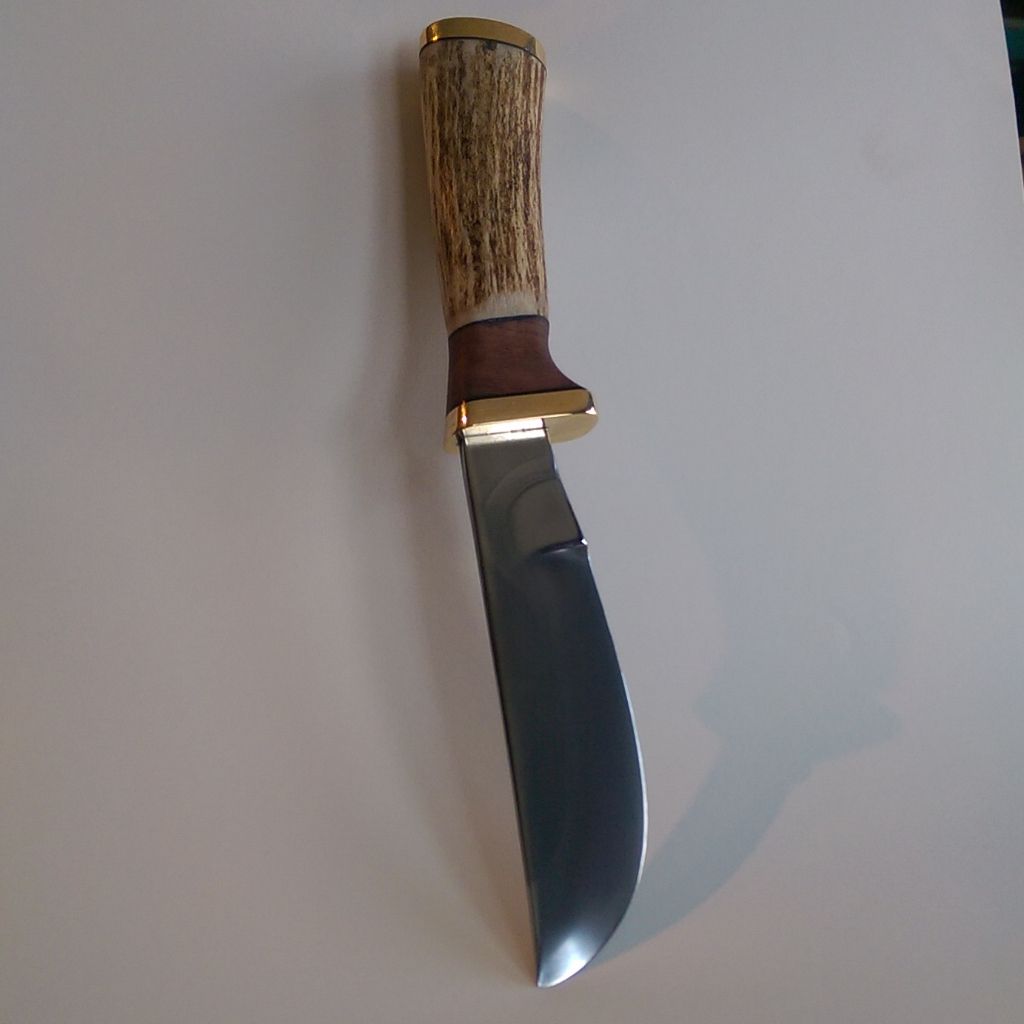

Thanks to everybody for the kind words! Doug, I'm fully aware of the controversy surrounding Mr. Fowlers methods. However I don't think that not talking about anything and going and playing in our separate corners all the time will get anyone anywhere. That's one reason I love working and conversing and trading ideas in the circles I am in. Nothing is dismissed at face value or because it doesn't align with whatever "bible" you abide by. Every one of them has and is still willing to experiment, test and trade knowledge about everything knife related. Instead of quoting passages from the Verhoeven book I'd much rather hear about your personal findings with 52100 (as that is the only steel in question). How you came about them, how you personally tested them and the parameters in which you worked. I'm open and willing to new ideas if you have something to substantiate your beliefs on. That's why I do choose to align myself with Ed and Chris and all of the talented men of the HEPK. Every question I ask gets answered in laymens terms, making it understandable, with physical evidence and tests that I have personally witnessed numerous times. I have not once "spun my wheels" while working under their tutelage. My blades have come out great and performed exceptionally well at the tasks they were designed to do.