John Wilson

Well-Known Member

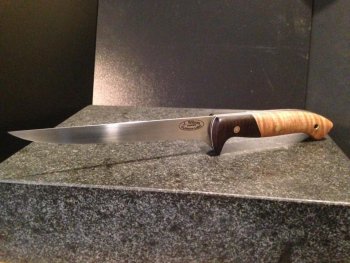

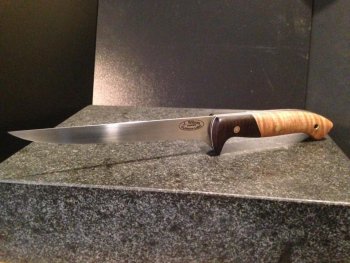

Some quickie pics of my first fillet knife. I just finished it today. I used .070 AEB-L for the 6-1/2 inch blade. Finished dimensions are .066 at the ricasso (not much ricasso, it's sharpened halfway around the bend) and ends at .020 at the tip. I took the edge to .005 before sharpening.

The handle is figured Asian Satinwood and East Indian Rosewood.

There was previous thread about having fillet knives sent out for heat treatment and getting them back warped. I have to say that Peters' did a great job. I sent them four blanks, all from .070 stock and they all came back straight.

I'll take better pics if I have time. The customer has been waiting on it patiently so I may have to take good pics of the next one.

The handle is figured Asian Satinwood and East Indian Rosewood.

There was previous thread about having fillet knives sent out for heat treatment and getting them back warped. I have to say that Peters' did a great job. I sent them four blanks, all from .070 stock and they all came back straight.

I'll take better pics if I have time. The customer has been waiting on it patiently so I may have to take good pics of the next one.