J

Josiah Solberg

Guest

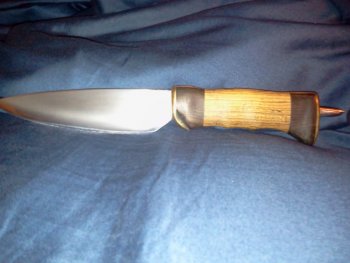

This is actually the blade I forged at the Central Florida Hammer-In 2011. I got help, pointers and tips from all the experts on the blade. It started its life as a bar of 1080 (Thanks Mike B.), then became what it is today. I did the handle in two woods; black and white ebony for the front and back ends (Thanks Craftsmans Supply, Tampa), and tiger wood in the middle. I used brass stock for the bolsters (Thanks Rob G.). I made it full tang, but finished the end of the tang into a butt-spike...which I have spiked my palm on a couple of times. I'll get over it; if I dont, I'll peen it over and round it off, Haha.

She is differentially heat treated and harder than my Nicholson files now, but not brittle at all. She takes and keeps an edge well. Now I need to do a sheath.

She is differentially heat treated and harder than my Nicholson files now, but not brittle at all. She takes and keeps an edge well. Now I need to do a sheath.