leafspring

Member

Hi all, i'd like to share my knife making story...

forgive my poor English and pics.

Being a while as a silent reader in this forum and dreaming to have a good knife, I finally made a step to make it on my own.

I found the tutorials in this forum are very useful ad yet helpful.

One day my boss came with a new set of files and told me to scrap the old ones. It just sparked my desire to make knife from old file also to overcome the boredom of a long shift in remote drilling camp in Arab desert.

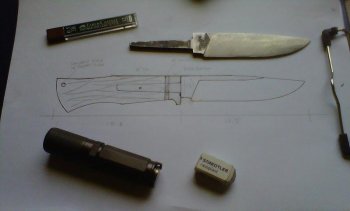

I started to put together my imaginations from pics i saw here, and came out to make a 4.5" clip point.

File was annealed by a fellow welder with cutting torch. Cut and rough shaped with bench grinder.

File the bevel as a flat ground

Done filing and scratch removal with 180 grid sand paper, I came back to the welder to harden. It was partially hardened and quenched in motor oil.

I was lucky to find a brass, Al plate and piece of oak in welder's shop. Must be useful for handle. I put the together with epoxy glue and a 1/8" brass pin.

Then work on the handle with half round file and sand paper.

I was tempted to put a force patina on it. i used Henna after seeing an oxidized spoon used by a friend to prep it.

Last thing i removed the oxidation with metal polish paste. I was surprised a crisp temper line just appeared on the blade.

It was sort of orgasm to me seeing this knife done:biggrin:

Please feel free to criticize.. since my skill is still million miles away from yours.

forgive my poor English and pics.

Being a while as a silent reader in this forum and dreaming to have a good knife, I finally made a step to make it on my own.

I found the tutorials in this forum are very useful ad yet helpful.

One day my boss came with a new set of files and told me to scrap the old ones. It just sparked my desire to make knife from old file also to overcome the boredom of a long shift in remote drilling camp in Arab desert.

I started to put together my imaginations from pics i saw here, and came out to make a 4.5" clip point.

File was annealed by a fellow welder with cutting torch. Cut and rough shaped with bench grinder.

File the bevel as a flat ground

Done filing and scratch removal with 180 grid sand paper, I came back to the welder to harden. It was partially hardened and quenched in motor oil.

I was lucky to find a brass, Al plate and piece of oak in welder's shop. Must be useful for handle. I put the together with epoxy glue and a 1/8" brass pin.

Then work on the handle with half round file and sand paper.

I was tempted to put a force patina on it. i used Henna after seeing an oxidized spoon used by a friend to prep it.

Last thing i removed the oxidation with metal polish paste. I was surprised a crisp temper line just appeared on the blade.

It was sort of orgasm to me seeing this knife done:biggrin:

Please feel free to criticize.. since my skill is still million miles away from yours.