You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My mini forge build

- Thread starter Gliden07

- Start date

Gliden07

Well-Known Member

Looking good. Hope the burner works out for you.

Thanks Ty! I hope so too, but if it doesn't I'll build another one!! LOL! I'm having fun building it. Worked on the legs a little tonight and designed in a shelf that can pull out to hold longer pieces. Couple more pieces a clean up and paint to make it pretty. I have to get some IRC for the interior and I'm debating on wether I should use some refractory cement to bond the cut bricks together? If anyone has any suggestions I'm open to them!

Gliden07

Well-Known Member

Ok here is the Mini Forge with all the fab work done painted up and stylin!! .

Need to get some IRC coating for the chamber. Wondering if I should get some Furnace cement to stick all the bricks together?? Now all that needs to happen is the burner works??

Need to get some IRC coating for the chamber. Wondering if I should get some Furnace cement to stick all the bricks together?? Now all that needs to happen is the burner works??

Attachments

Dennis Morland

KNIFE MAKER

You did a really nice job making that look nice. Especially cutting the hole. I hope it works as good as it looks. If so - watch out knife blanks!

Gliden07

Well-Known Member

Well I stuck all the refractory bricks together with Hi Temp furnace cement, rating said it was good for 2700F. Have to order IRC now. Gonna let the cement dry for the weekend and hopefully fire it Monday quick to help dry cement and see if the burner will work in forge?? Fingers crossed!!

Kevin Zito

KNIFE MAKER

Man this is awesome!

Gliden07

Well-Known Member

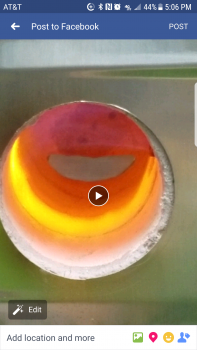

So I lined the forge with the IRC. Night and day differene there is still a hot spot cross from the burner, from what I've read this is almost impossible to remedy it is a trait that an atmospheric burner has. But the forge now has an almost even Orange glow front to back (about the first 1/2" or so in front looks cooler, I'm sure this is due to the open chamber constantly cooling that area?). I heated a 3/4" cold chisel in the moderately heated forge about 2-3 min to a bright Orange color in about 2-3 more min! I have no way to check temp but believe I should come close to Forge welding temp with this setup? This was a fun and relitivly cheap project. All toll with the little bits I had to buy I am into the forge without regulator for $50-60 and that is lined with the Metrocote from Wayne Coe including the shipping. I had all the steel from scrounging and the Regulator, if I include the regulator no more than $80. It was a fun project.