Chris Railey

Well-Known Member

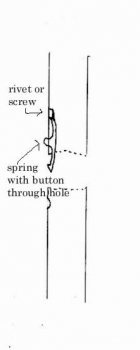

In the coming weeks I will be making a cane sword. Really cool project and I have everything laid out in my mind EXCEPT how the top of the handle will attach to the cane/sheath part so it will function as a proper cane. I thought about recessing strong magnets in both pieces to make the connection but I would rather have a decent mechanical connection. Has anyone else made one of these and perhaps has a solution? Even if you have not made one can you think of a solution obtainable without the use of a mill or lathe...neither of which I have. I do have access to a pipe threader and to someone who knows how to use it so maybe I can go that route?

Last edited: