Gliden07

Well-Known Member

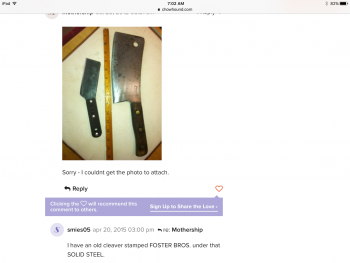

Dont know when I'm gonna work on this but. This was a clever that was giving to me it is in decent shape but the handle was horrible on it and the pins were Lead!! I'm gonna reshape it and put a hidden tang on it, so I can get the handle fixed.