The last time I put down a sand point I was just a kid, in Nebraska! We pulled an old well head that had been down about 40 yrs. My dad told me him and his brother used to pull them with bars and a chain.

We pulled with chain and bar and barely moved it. We put a 5 ton hydraulic jack on it and blew the cylinder. My old man went to a friend and borrowed two old 15 Ton railroad jacks. We slid an I bean across the well shaft, chained to the pipe. We used the bottom foot on those railroad jacks and lifted on the I beam! We must have snapped that pipe a dozen times but when we finally got it out and, we found out why.

The pipe was 2" with a 2" well head. Problem was the well head had about 3" of corrosion all the way around it. So we pulled a 5" head out of a 2" hole. The sand at the depth of the well head had just enough iron in it that it literally adhered to the head! That is what eventually choked off the water supply from the well. The water was barely able to filter through the corrosion around the head! Weren't no problem to put down the new drive point well head! We went back with a 3" head, on a 2" pipe! Didn't take a lot of effort to drive it back down the hole!

As best as I can remember my old man told me we had to stay at the depth of the water so we went back to the depth of the old well head. We used an old pump jack converted to electric. But we had to prime the pump. You have to have water in the pipe for it too draw. Once you pull the initial water the pump will maintain the water. How ever if you

break the pump loose or the pump looses its prime due to bad seals. You got to start all over!!

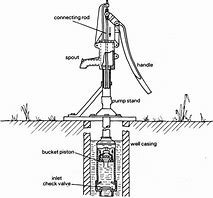

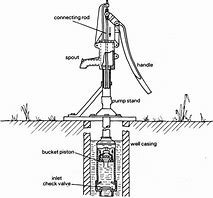

Her is a schematic of how a pump jack works!

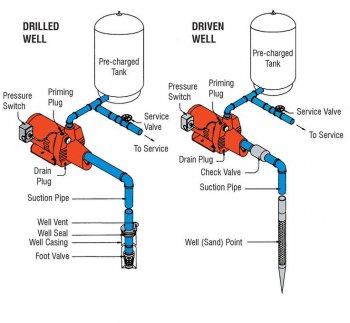

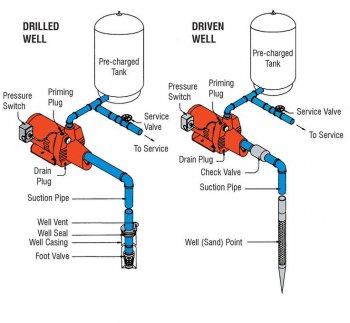

A modern electric well head works the same way, sort of! To get that pump to draw the water you have to take the priming plug out and stand there with a bucket of water priming the pump until the well creates enough pull to bring up the water from the well! As soon as you see it pumping get the plug screwed back in so you don't loose the prime. As long as none of your seals are bad the pump will hold a level on the water! I have seen it where you might have a small leak on the seals and if you don't use the pump often it will need to be primed again when you use the pump! Priming and seals are what makes a pump or well work. The only other culprit would be if the water table has changed. You may have to go deeper to get to good water!

Boy you just brought back some memories I haven't accessed in a while!!! Hope some of that helps!