Hello everybody, my wife bought me a propane fired forge for father's day because the boys and I were talking about wanting to make some knifes.

The only thing I had on hand to work with was some mystery metal round bar about .75" OD. So I stuck in in the forge and chiseled off a piece to start hammering on.

I hammered it down to about 1/4" in thickness, then started shaping the blade to be a straight taper from the spine to the edge. I left the handle long to have something to hold onto and ground it down to size afterwards.

I spent a few hours with a Mill Bastard file and got to this point.

The blade ended up being about 7" long and didn't look right, so I cut an inch off the end and reshaped it.

Once I had it about looking like a knife, I put it back into the forge and heated until it turned non-magnetic and quenched in some tractor hydraulic fluid. It turned out fairly straight and only needed a few love taps to get it all in line again. I heated up the oven to 450 and tempered it for an hour, then turned off the stove and let it cool over night.

I found Jantz supply for knife stuff and ordered a brass finger gaurd. I filed it out to fit the tang and silver soldered in place.

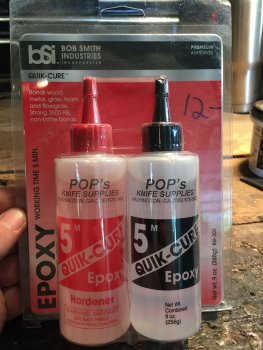

While clearing brush this spring we cut down a Cedar tree and I saved part of the stump. I cut some scales out of part of it and epoxied them in place with some Harbor freight 2 part quick set epoxy. I don't know if I didn't degrease the shank good enough or what, but the glue didn't stick to the metal and started coming off while I was shaping the wood on the belt sander.

Sooooo, I thought I would stop and ask for some assistance. What kind of epoxy should I use to glue the scales on?

I'm hoping that I can just sand the harbor freight glue off and go back with something better.

I have some 5/16" brass round stock that I was thinking of using at a rivet to hold the handle together after the glue has set. Or if I have the right kind of glue, will I need to rivet, or just use some pins. In looking at it, the 5/16" looks to be abit on the large side, so I may have to order in something smaller. Any help on what size they should be?

I saw a knife at a gun show that used roll pins instead of like a brass or silver/nickel...

I did order some 1080 and 5160 in different sizes to use after this one is done. I haven't sharpened the blade yet, but it will shave on parts of it already, so I taped it up with a strip of gorilla tape while shaping the handle.

I know that I have probably made a bunch of mistakes, so... Any constructive comments would be greatly appreciated.

The only thing I had on hand to work with was some mystery metal round bar about .75" OD. So I stuck in in the forge and chiseled off a piece to start hammering on.

I hammered it down to about 1/4" in thickness, then started shaping the blade to be a straight taper from the spine to the edge. I left the handle long to have something to hold onto and ground it down to size afterwards.

I spent a few hours with a Mill Bastard file and got to this point.

The blade ended up being about 7" long and didn't look right, so I cut an inch off the end and reshaped it.

Once I had it about looking like a knife, I put it back into the forge and heated until it turned non-magnetic and quenched in some tractor hydraulic fluid. It turned out fairly straight and only needed a few love taps to get it all in line again. I heated up the oven to 450 and tempered it for an hour, then turned off the stove and let it cool over night.

I found Jantz supply for knife stuff and ordered a brass finger gaurd. I filed it out to fit the tang and silver soldered in place.

While clearing brush this spring we cut down a Cedar tree and I saved part of the stump. I cut some scales out of part of it and epoxied them in place with some Harbor freight 2 part quick set epoxy. I don't know if I didn't degrease the shank good enough or what, but the glue didn't stick to the metal and started coming off while I was shaping the wood on the belt sander.

Sooooo, I thought I would stop and ask for some assistance. What kind of epoxy should I use to glue the scales on?

I'm hoping that I can just sand the harbor freight glue off and go back with something better.

I have some 5/16" brass round stock that I was thinking of using at a rivet to hold the handle together after the glue has set. Or if I have the right kind of glue, will I need to rivet, or just use some pins. In looking at it, the 5/16" looks to be abit on the large side, so I may have to order in something smaller. Any help on what size they should be?

I saw a knife at a gun show that used roll pins instead of like a brass or silver/nickel...

I did order some 1080 and 5160 in different sizes to use after this one is done. I haven't sharpened the blade yet, but it will shave on parts of it already, so I taped it up with a strip of gorilla tape while shaping the handle.

I know that I have probably made a bunch of mistakes, so... Any constructive comments would be greatly appreciated.

Last edited: