norseman

Active Member

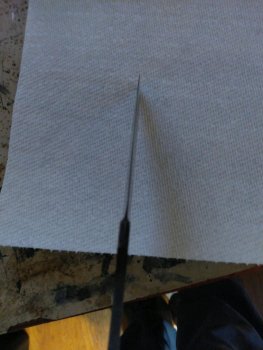

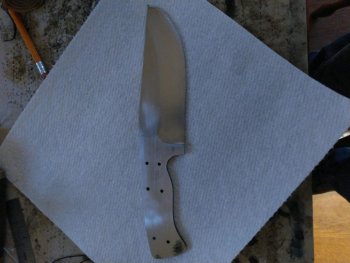

I watch the video of the DYI build, didn't understand the need - I do now.

Looks to me like another candidate to to follow myself and so many others, in the DIY build of a Surface Grinder Attachment. I promise you won’t regret it!