Part of the equation, as to if that power unit will be usable.... is the diameter of the cylinder, the desired rate of travel, and how much PSI your willing to use/chance.

I looked all over the Coal Ironworks site, and couldn't find what diameter cylinder they use.

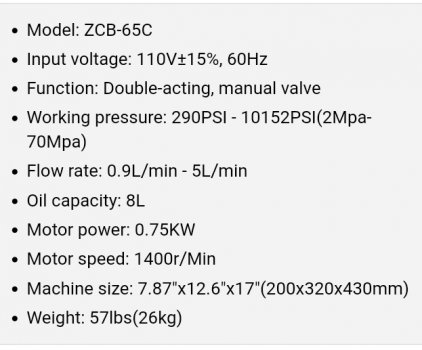

The stats on your power unit, that make me think it would not work, is the flow rates..... ( yours says .9liters to 5liters), the max flow of 5 liters per min is equal to only 1.3 gallons per min. That might move a very small diameter cylinder, at a painfully slow rate of travel (talking like a 3-4" cylinder), but you'd have to run pressures that I would call dangerously high to achieve it.

The reason I think that, is because the smallest pump that would make my old 6" diameter cylinder press run at just a tad over 1" per second, was 11.5 gpm (gallons per minute) when turned at 3450rpm, and using a max of 2000psi. My current press, Orang Crush, runs a 10" cylinder, that travels a tad over 1 inch per second, and it's pump is 28 liters per minute... which equals 7.3 gallon per minute, running off a 4 cylinder Kubota diesel engine, turning at 1800rpm, with a max psi of 2200.

Here's the thing with forging presses..... they are very dynamic, in that the amount and direction of forces are directly related to what you put in it, how you put it in, and how well or how poorly whatever you intend to press is centered of the the force/ram. Until you gain a bit of experience, I highly recommend using extreme caution....and even once you have experience, the first time you fail to respect it.... it will get you! The common mentality when someone is newly exposed to/using a forge press is that they can "squash" anything, when in reality, a press's strong suit if finesse NOT speed.

OK..... now to Ed's soapbox safety rant.

When putting together/building a press, you must always take into account what will be the weakest link in the entire hydraulics system! Whatever that link might be, it MUST be able to withstand at least 1/2 again, and I personally prefer DOUBLE the PSI your pump is putting out. The way I have always dealt with it is a adjustable "bleeder valve" placed in the system, and set to bleed off pressure before an unsafe PSI is reached. The max PSI on Orange Crush is set to 2000psi. In my system it is built into the main valve body that controls in/out actuation of the cylinder, but it can also be added as an auxiliary component. Why so anal about this? Because IF you were to get a pinhole leak in a system pushing 2000psi..... you would not see the fluid....but it would cut like a Star Wars light saber! I learned this when working in a "high temp hot water" heating plant on an Air Force Base..... the system operated at 350psi.... and when a leak occurred, we could hear it, but could not visually see the leak....only the damage it was causing IF it happened in a spot that afford that luxury. The way we found those leaks, was to go along parallel to a pipe that we heard whistling/suspected, with a corn broom waving up/down in front of us. When the straws were cut off the broom....we had found the leak. If a 350psi pinhole will cut the straws off a broom head..... image what 2000 psi of hydraulic fluid/mist would do.

OK, rant completed.