You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OPauls Knife Picture Thread

- Thread starter opaul

- Start date

Jon Buescher

Well-Known Member

I saw this one on FB did you pick a handle material yet? you have such a good eye for matching materials that I couldn't think of anything you probably hadn't already thought of

opaul

Well-Known Member

Not yet. Dennis suggested snake wood but I don’t have any on hand.I saw this one on FB did you pick a handle material yet? you have such a good eye for matching materials that I couldn't think of anything you probably hadn't already thought of

Thanks.

Dennis Morland

KNIFE MAKER

Not yet. Dennis suggested snake wood but I don’t have any on hand.

Thanks.

OPaul I suggested snakewood because it wold somewhat match the pattern in the Damascus. You cold use a patternless piece of wood like Blackwood or even a nice bit of ironwood. With that blade just about anything will look good.

tkroenlein

Well-Known Member

Don't see those every day. I'd accept a full blown reprimand from my CFO to bring that home.

opaul

Well-Known Member

Yep. The 3” are hard to come by. This is a 1980 model.Don't see those every day. I'd accept a full blown reprimand from my CFO to bring that home.

tkroenlein

Well-Known Member

Rare as hens teeth. I'd CC a wheel gun if I had a 3" K.

MTBob

Well-Known Member

Opaul, this is a very impressive portfolio of knife craftsmanship. A couple questions, if I may:

- How long have you been making knives?

- Do you make knives as a business and, if so, is it full time?

- Do you keep an inventory of the material used in a knife, specifically the blade steel and heat treatment? If so, how do you do that?

Bob

- How long have you been making knives?

- Do you make knives as a business and, if so, is it full time?

- Do you keep an inventory of the material used in a knife, specifically the blade steel and heat treatment? If so, how do you do that?

Bob

Jon Buescher

Well-Known Member

I’ve got one that belonged to my Grandfather looks nearly identicalYep. The 3” are hard to come by. This is a 1980 model.

opaul

Well-Known Member

Thank you!Opaul, this is a very impressive portfolio of knife craftsmanship. A couple questions, if I may:

- How long have you been making knives?

- Do you make knives as a business and, if so, is it full time?

- Do you keep an inventory of the material used in a knife, specifically the blade steel and heat treatment? If so, how do you do that?

Bob

I’ve been making knives about four years now. I retired 12/16 and started making knives regularly beginning mid 2017.

I wouldn’t consider myself a full time knife maker but I spend a lot of time in the shop.

As far as material I typically use the 10xx series steel. I have a Evenheat oven so I have preset programs for the steels I use. I quench in Parks oil and temper in the Evenheat oven. I also use W2 and O1 steels and follow the HT guidelines - also programmed in the oven.

I hope this helps! Let me know if you have more questions.

opaul

Well-Known Member

Ok. I’ll try to answer as best I can.awesome knife! i have question, what do you consider to make a quality knife?

A knife in itself is of quality of the material that goes into it - steel and fittings. Poor material = poor quality. The steel has to be HT’d properly and tempered correctly. The handle material suitable and securely fastened and fitted.

Then it’s all personal from there. If all these things are done to the best of your ability and the fit and finish doesn’t mirror the time and effort you have spent to make a knife will result in a knife of substandard construction.

It’s been said many times on this forum - fit and finish and make your next knife better than the last one.

Wax on/wax off.

MTBob

Well-Known Member

This is really helpful. In fact I find your knife photos inspiring and challenging, your workmanship sets a pretty high bar for some of us wanna-be knife makers. As I like to say to my friends - I make knives, but I'm not yet a "Knife Maker". Seeing what you have done motivates me to spend more time in the shop.Thank you!

I’ve been making knives about four years now. I retired 12/16 and started making knives regularly beginning mid 2017.

I wouldn’t consider myself a full time knife maker but I spend a lot of time in the shop.

As far as material I typically use the 10xx series steel. I have a Evenheat oven so I have preset programs for the steels I use. I quench in Parks oil and temper in the Evenheat oven. I also use W2 and O1 steels and follow the HT guidelines - also programmed in the oven.

I hope this helps! Let me know if you have more questions.

A comment: Also interesting is your apparent focus on high carbon steel. I would have thought that having an electric oven you would be inclined to also use stainless steels. Is there a reason you prefer high carbon over stainless?

And, to follow up on an earlier question - I phrased it wrong earlier - Do you keep track of the actual steel used in the various knives shown in your photos? For instance, If I were to pick one of the knives shown above in your photo album, could you tell what the steel is and what heat treatment you use? After making dozens of knives I'm finding it harder to keep track of what's in the blade.

Thanks again for taking time to answer these questions, much appreciated!

opaul

Well-Known Member

I'm very flattered, thank you very much.This is really helpful. In fact I find your knife photos inspiring and challenging, your workmanship sets a pretty high bar for some of us wanna-be knife makers. As I like to say to my friends - I make knives, but I'm not yet a "Knife Maker". Seeing what you have done motivates me to spend more time in the shop.

A comment: Also interesting is your apparent focus on high carbon steel. I would have thought that having an electric oven you would be inclined to also use stainless steels. Is there a reason you prefer high carbon over stainless?

And, to follow up on an earlier question - I phrased it wrong earlier - Do you keep track of the actual steel used in the various knives shown in your photos? For instance, If I were to pick one of the knives shown above in your photo album, could you tell what the steel is and what heat treatment you use? After making dozens of knives I'm finding it harder to keep track of what's in the blade.

Thanks again for taking time to answer these questions, much appreciated!

I do venture into stainless from time to time. I've done two Vegas Forge stainless damascus blades. I'm pretty sure I will do more SS but I just prefer to work with the carbon steels.

Yes, I do keep track of the steels I use in particular knives. I may have missed several but for the most part yes.

Bruce McLeish

Well-Known Member

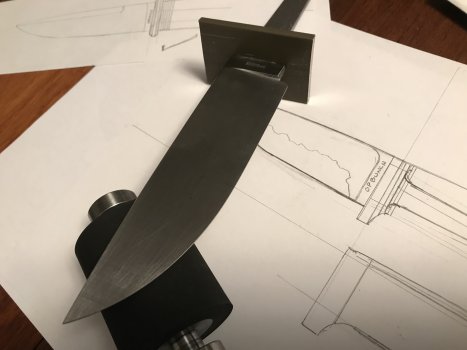

Nah. Looks groovy. Um. Um.Got the guard fitted today on this blade. Nickel silver. Do you guys think it’s to square?

View attachment 76140