You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Playing with my laser.

- Thread starter Jesse Latham

- Start date

MTBob

Well-Known Member

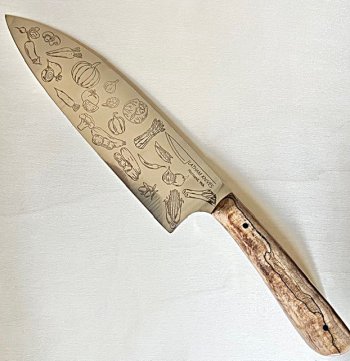

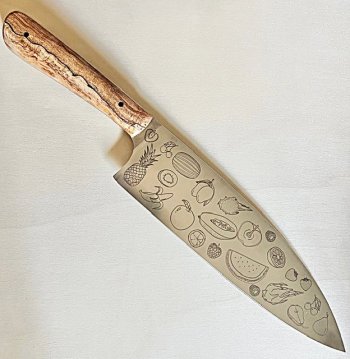

I love your creativity, nicely done!Like most of you who use one, I've lasered a bunch of different things on blades. This is the latest. AEB-L with spalted maple. If you're right-handed you can cut veggies, if left-handed you can cut fruit. Lol

Which laser do you have?

Jesse Latham

Well-Known Member

I have a 20w Atzer diode. Like most it makes me want bigger and better.Which laser do you have?

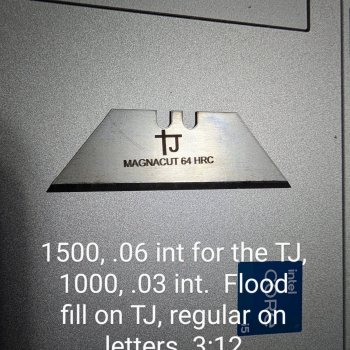

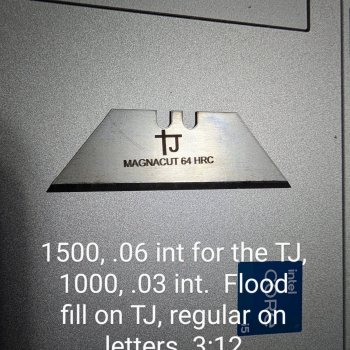

Picked up a 2W IR laser and started playing with it! It's the Sculpfun IR 2 that was on sale recently and I mounted it to my Anolex CNC machine. I found out that the interval makes a HUGE difference!! The IR beam is .03mm wide, so I set the interval as that and kept getting gold color. I may go back and see what setting the gold on the left was at; it's kinda neat and different! No idea how it will hold up though? Or do the gold and then a couple extra quick passes to clean up the oxide and leave it silver?

A guy on FB recommended going to .01mm interval and bam, nice black etch!

.02 is a dark brown, but .015 seems to stay black and is MUCH faster to do! These are on the tangs of some magnacut blades, .015mm interval and 200mm/min. About 12 minutes to do. The etch catches the fingernail about the same as my etching does, so it gets good depth!

Not bad for a $350 laser module!!

I was able to engrave some anodized aluminum and it removed metal, not just the anodizing. Did a key as well, too! I gotta try my Mokume (copper/nickel silver) coin that I made and see what it will do on that!

A guy on FB recommended going to .01mm interval and bam, nice black etch!

.02 is a dark brown, but .015 seems to stay black and is MUCH faster to do! These are on the tangs of some magnacut blades, .015mm interval and 200mm/min. About 12 minutes to do. The etch catches the fingernail about the same as my etching does, so it gets good depth!

Not bad for a $350 laser module!!

I was able to engrave some anodized aluminum and it removed metal, not just the anodizing. Did a key as well, too! I gotta try my Mokume (copper/nickel silver) coin that I made and see what it will do on that!

Ok, so I am running my lasers on a desktop CNC control board. I found out my CNC S value (spindle speed) was 10,000, but my laser S value was only 1,000. Oops!!! My lasers were really at 10% power when set to 100%! And I had my X speed at 500mm/min and y and 400mm/min, so that was it's max speed.

Still playing with settings:

On a real blade that I am using as a tester:

And I put my 20W diode back onto the machine at full power. 5% trace setting leaves a tiny line in bloodwood or walnut pieces. 100%, 200mm/min cuts through 1/8" hardwoods pretty nicely!

Still playing with settings:

On a real blade that I am using as a tester:

And I put my 20W diode back onto the machine at full power. 5% trace setting leaves a tiny line in bloodwood or walnut pieces. 100%, 200mm/min cuts through 1/8" hardwoods pretty nicely!