Keith Willis

Well-Known Member

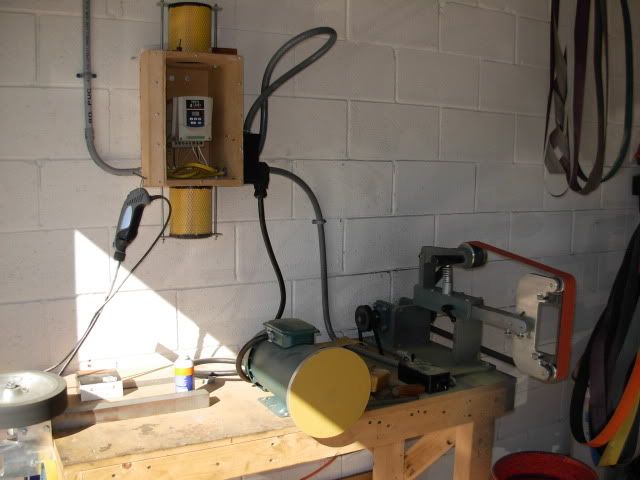

My grinder has a 1hp motor that is wired for 110.My shop is not wired for 220,but I can do so very cheap,I have everything I need to wire it,and I will do so as soon as I am able.

My question is,until I am able to purchase a larger motor,If I run the wire for 220 and hook my 1 hp motor to 220,will there be enough difference in torque,that will make it worth the effort.

I will have a 1 1/2 hp or bigger, as soon as I save a little money.

Thanks,

God bless,Keith

My question is,until I am able to purchase a larger motor,If I run the wire for 220 and hook my 1 hp motor to 220,will there be enough difference in torque,that will make it worth the effort.

I will have a 1 1/2 hp or bigger, as soon as I save a little money.

Thanks,

God bless,Keith