Scandinavian knife WIP #finnished# (56k Beware, Pic Heavy)

If it is in the wrong forum then I apologise.

I have been taking some pictures in the workshop tonight. It is the first time in a while since I have had the wiring redone

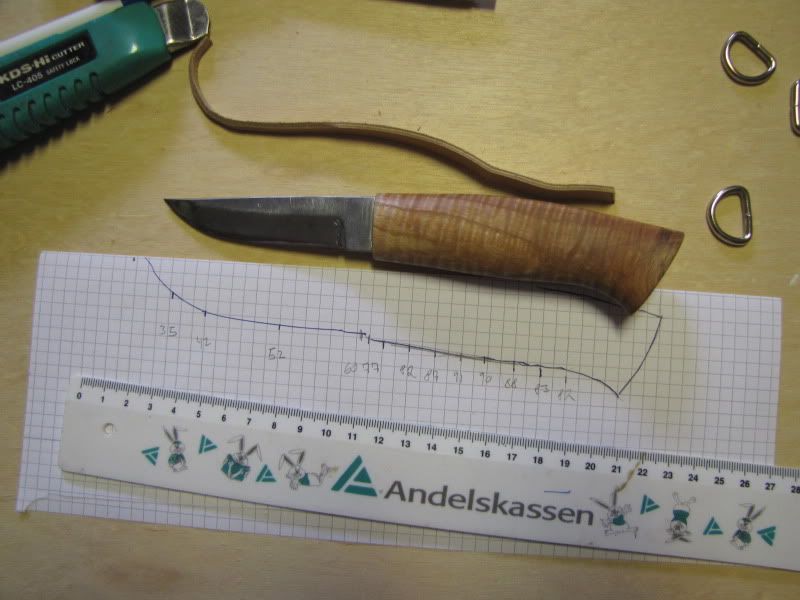

Knifeblade and a piece of wood:

The first plan was a One-piece scandi, but it isn't anymore.

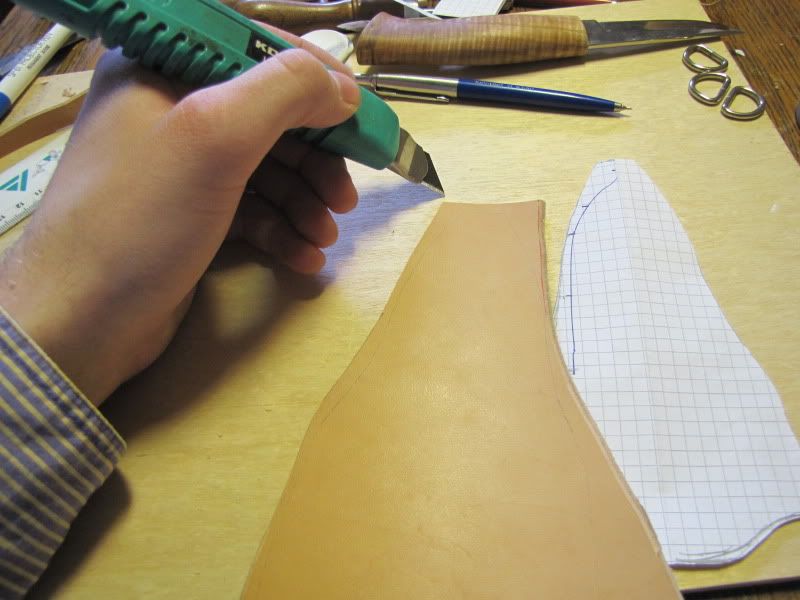

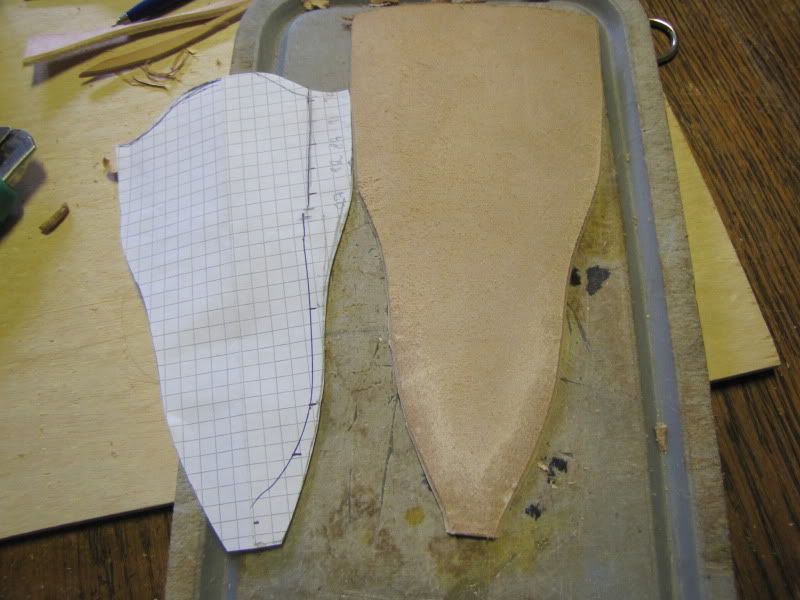

I took the drawing I have made of the handle and cut it out with a pair of scissors, then traced it on to the wood, a nice piece of kiln-dried ash, dry as bone, hard and very tough wood. It is nice to work in, but it requires cleanliness, metaldust hidden in a file, to much graphite from a pencil or dirty sanding paper will smudge the woods pores.

Then a little work with a saw.

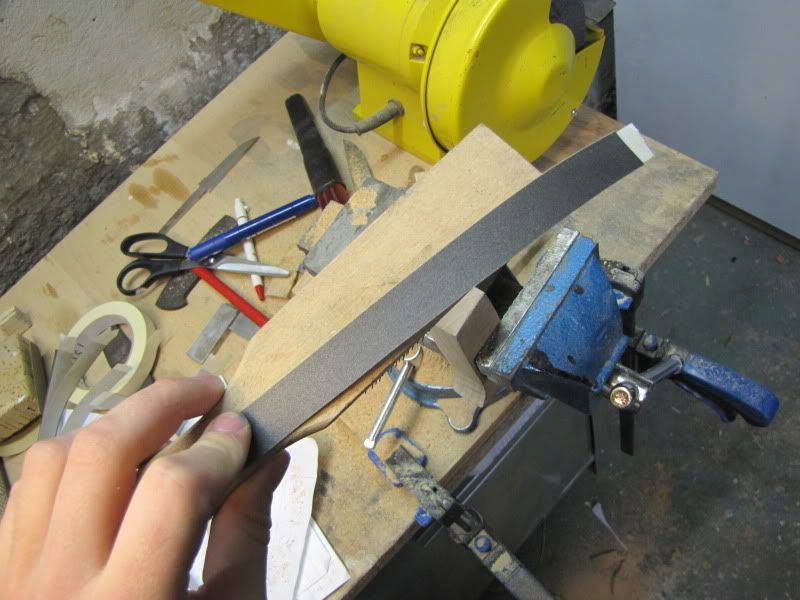

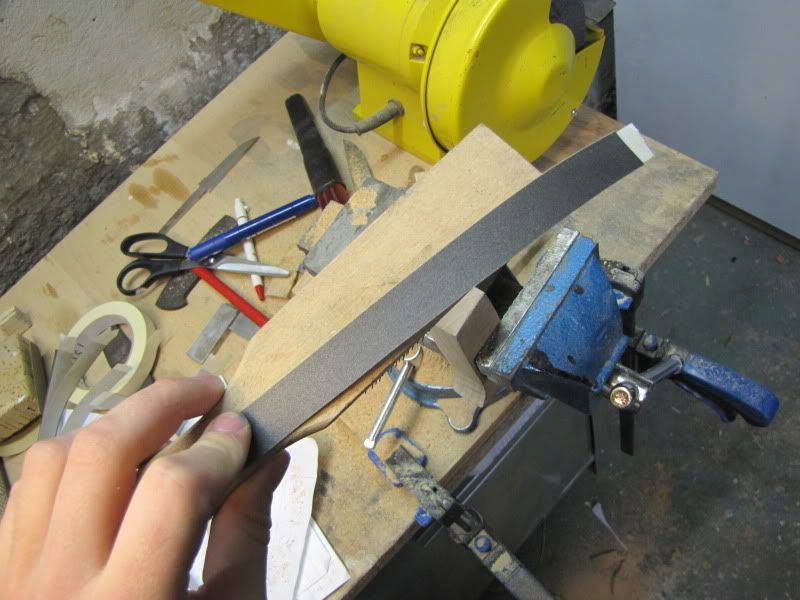

Then I use the farriers rasp you can see under the wood to shape it along with a halfround rasp, and then clean it up with a file.

Then I clean up the front end of the handle, first with an even finer file and then various grits of sandpaper up to 1200 grit.

A quick look to see the overall shape.

A little tip is to coat the backside of the sandingpaper with maskingtape, this relatively expensive wet'n'dry lasts much longer this way.

Cleaning up the front end I use a hard backing for grits 240 and 320, the rest I just use my thumbs.

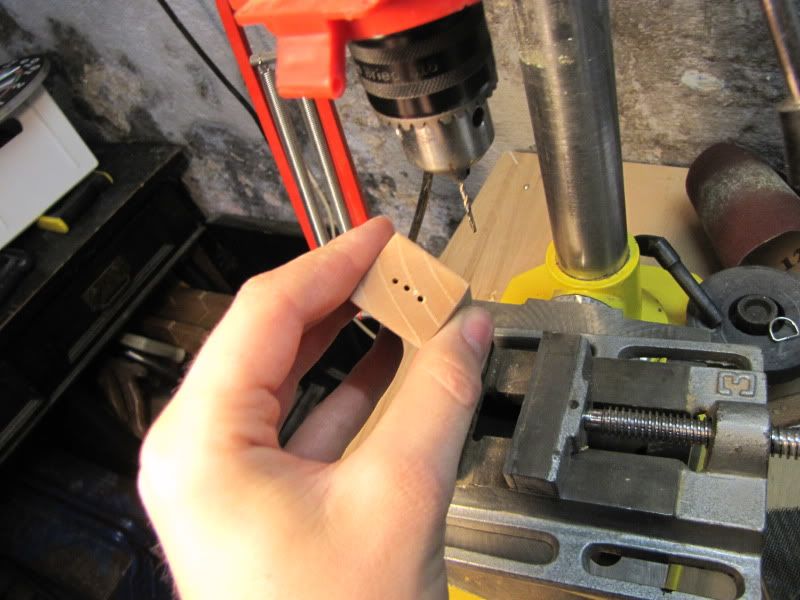

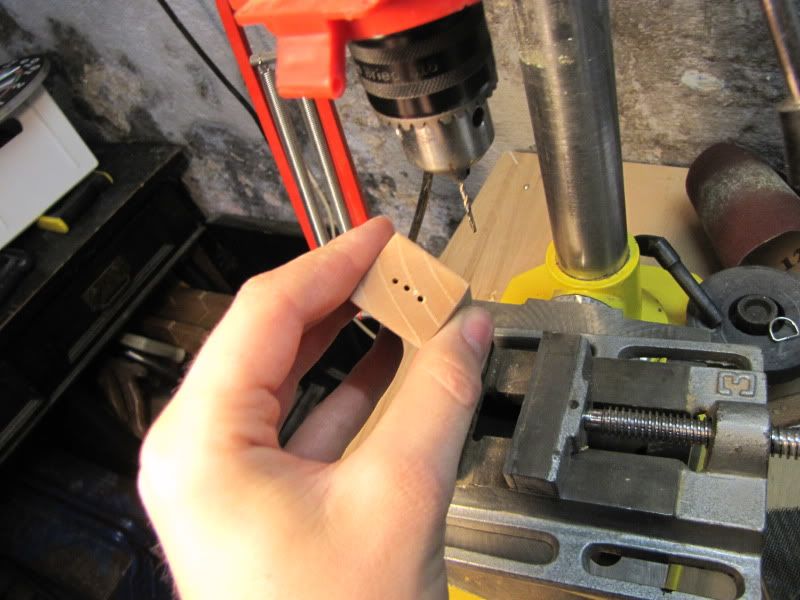

A quick view of the front end marked up for drilling.

Drilling the holes:

The first holes are just pilot holes, I drill further with a handdril and a 120mm drillbit This is not exactly protocol, and H&S Will not like it.

This is not exactly protocol, and H&S Will not like it.

Then I use a very small rasp and a small sawblade to widen the holes.

Almost done.

A couple of slips with the rasp and sawblade, and everything was ruined.

Now I have to cut of the front end and fit a bolster instead

If it is in the wrong forum then I apologise.

I have been taking some pictures in the workshop tonight. It is the first time in a while since I have had the wiring redone

Knifeblade and a piece of wood:

The first plan was a One-piece scandi, but it isn't anymore.

I took the drawing I have made of the handle and cut it out with a pair of scissors, then traced it on to the wood, a nice piece of kiln-dried ash, dry as bone, hard and very tough wood. It is nice to work in, but it requires cleanliness, metaldust hidden in a file, to much graphite from a pencil or dirty sanding paper will smudge the woods pores.

Then a little work with a saw.

Then I use the farriers rasp you can see under the wood to shape it along with a halfround rasp, and then clean it up with a file.

Then I clean up the front end of the handle, first with an even finer file and then various grits of sandpaper up to 1200 grit.

A quick look to see the overall shape.

A little tip is to coat the backside of the sandingpaper with maskingtape, this relatively expensive wet'n'dry lasts much longer this way.

Cleaning up the front end I use a hard backing for grits 240 and 320, the rest I just use my thumbs.

A quick view of the front end marked up for drilling.

Drilling the holes:

The first holes are just pilot holes, I drill further with a handdril and a 120mm drillbit

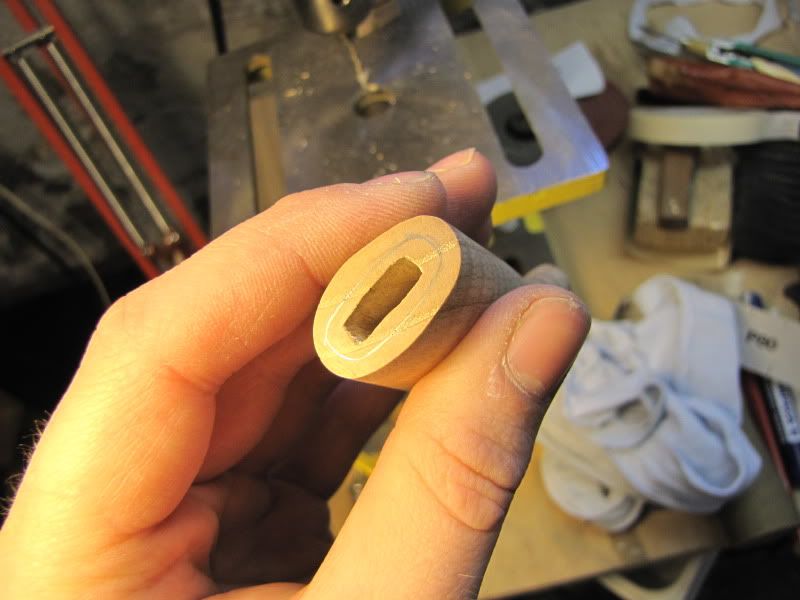

Then I use a very small rasp and a small sawblade to widen the holes.

Almost done.

A couple of slips with the rasp and sawblade, and everything was ruined.

Now I have to cut of the front end and fit a bolster instead

Last edited: