Sean Jones

Well-Known Member

That's a really nice setup Mr Hoffman...

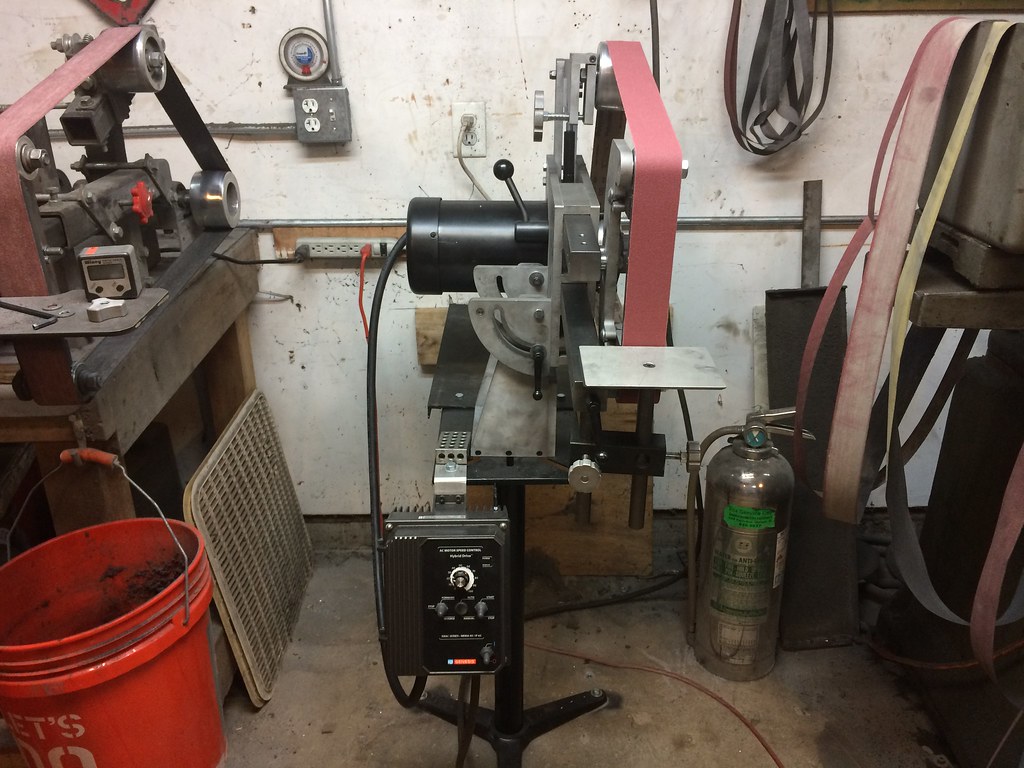

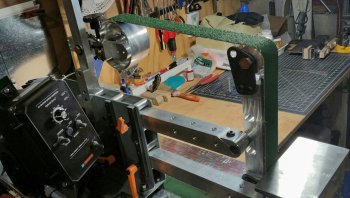

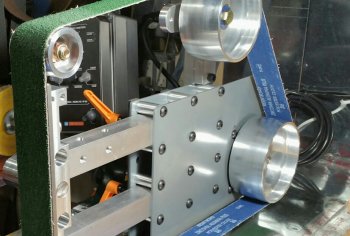

Untitled by AR Custom Knives (Andrew Riley), on Flickr

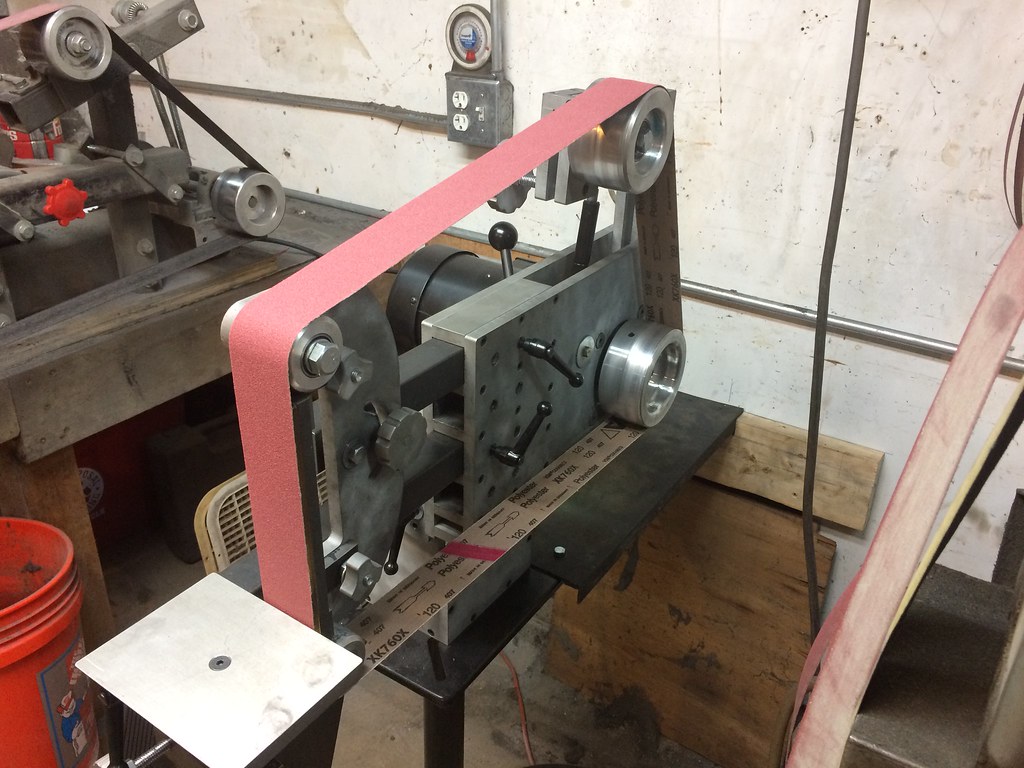

Untitled by AR Custom Knives (Andrew Riley), on Flickr Untitled by AR Custom Knives (Andrew Riley), on Flickr

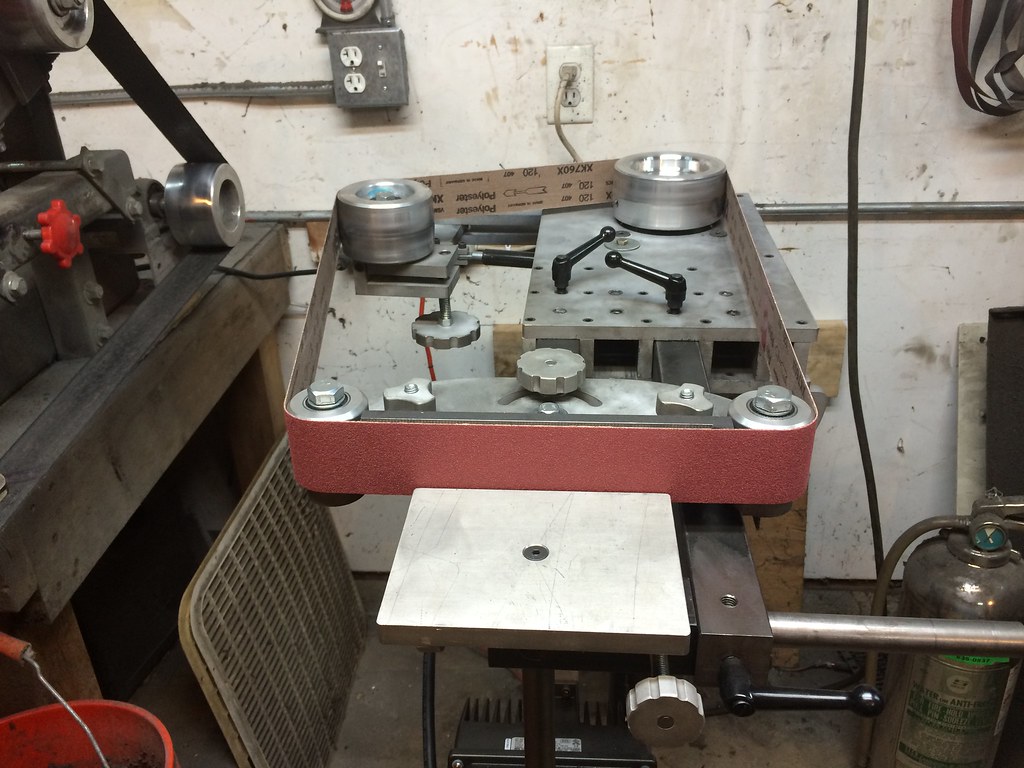

Untitled by AR Custom Knives (Andrew Riley), on Flickr Untitled by AR Custom Knives (Andrew Riley), on Flickr

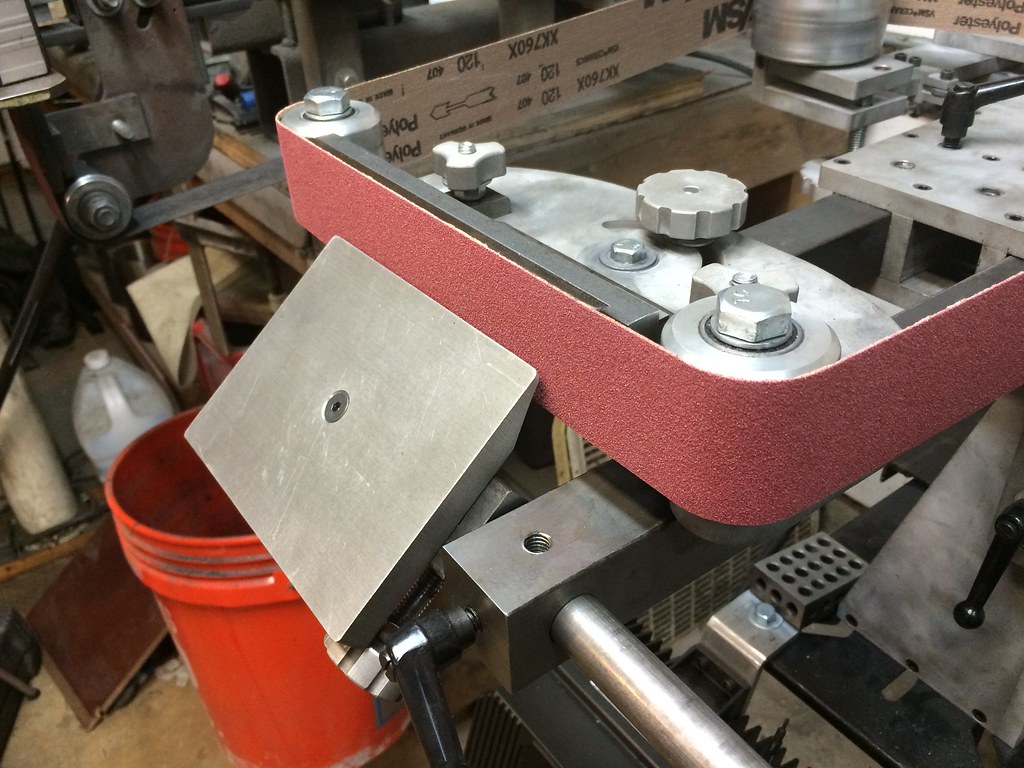

Untitled by AR Custom Knives (Andrew Riley), on Flickr Untitled by AR Custom Knives (Andrew Riley), on Flickr

Untitled by AR Custom Knives (Andrew Riley), on Flickr Untitled by AR Custom Knives (Andrew Riley), on Flickr

Untitled by AR Custom Knives (Andrew Riley), on Flickr

Works great. Kyle has a video and explanation of the details. But I can tell you it is very accurate and doesn't need much to make it track perfect.How does the tracking adjustment work @Nick Riggi? I’m looking at it and can’t figure out how it adjust?

Wow...I know mines not that smooth...though I'll give that test a try just out of curiousity.

That's a cool setup One Armed. Very nice.This is my home built. I designed it entirely. Didn’t use any existing designs to go by. Built from 1018 cold roll and 2024/7075 billet. Used the cast iron housing from my old HF 4x36 belt sander as a base. Powered by a 1.5hp, 3ph Dayton motor. Not really much I “don’t” like about it. It runs smooth as silk and is a pleasure to use. I am currently building a smaller flat platen for an 8” Granite platen surface as the 12” I designed in really is overkill & I just haven’t needed it. I’m also adding a second tooling arm port and making a fully adjustable work surface.