One

Banned

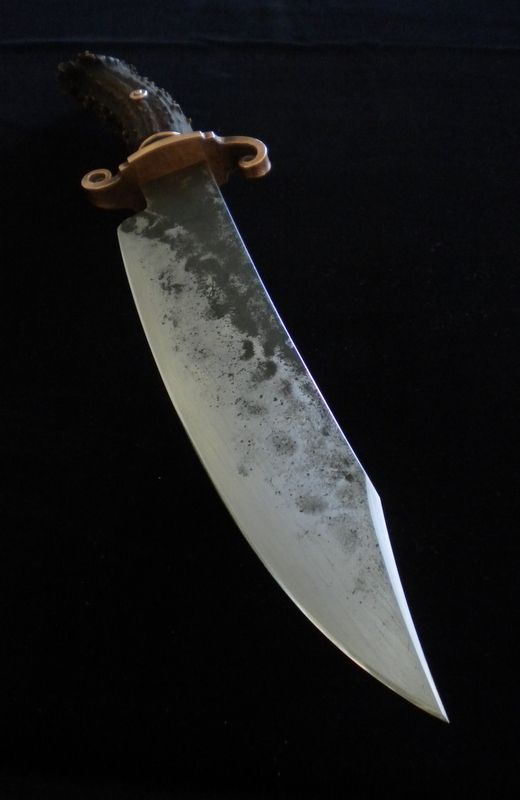

… another “handle first” construction.

I’m finding, (at least for myself), that with some of these irregular natural handle materials shapes/forms,… starting handle first and profiling the blades to go with them seems to help... We’ll see.

I’m planning on a scrolled guard and big 12 inch hammer finished bowie blade.

I’m finding, (at least for myself), that with some of these irregular natural handle materials shapes/forms,… starting handle first and profiling the blades to go with them seems to help... We’ll see.

I’m planning on a scrolled guard and big 12 inch hammer finished bowie blade.