kevin - the professor

Well-Known Member

Hello Everyone,

I have been working on this blade for several weeks now. It is an "inserted edge" construction, which has a long name in Chinese. You all know it probably better as san mai. There are two plates of welded and folded extra-improved plow steel cable sandwiching a plate of W2. The cable, especially after welding and folding, is much like low-manganese 1075 (it began life as steel with 80pts of carbon but less manganese than 1080 - I am always on the lookout for these types of resources).

So, outside plates have 75-80pts carbon, the center core has 100pts. This means that the cutting edge will have 100pts while most of the spine will be 80pts.

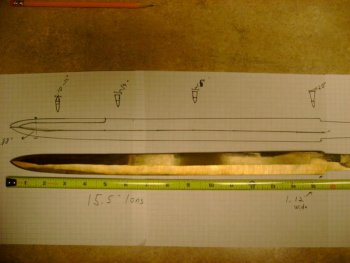

The first pics show the blade rough ground and clayed for heat treat.

I will hopefully walk you guys through polishing the redneck way, and we will end up with a blade with a nice grain structure from the cable on the back bevel and a vivid hamon on the W2 of the edge bevel. Hopefully.

I have been working on this blade for several weeks now. It is an "inserted edge" construction, which has a long name in Chinese. You all know it probably better as san mai. There are two plates of welded and folded extra-improved plow steel cable sandwiching a plate of W2. The cable, especially after welding and folding, is much like low-manganese 1075 (it began life as steel with 80pts of carbon but less manganese than 1080 - I am always on the lookout for these types of resources).

So, outside plates have 75-80pts carbon, the center core has 100pts. This means that the cutting edge will have 100pts while most of the spine will be 80pts.

The first pics show the blade rough ground and clayed for heat treat.

I will hopefully walk you guys through polishing the redneck way, and we will end up with a blade with a nice grain structure from the cable on the back bevel and a vivid hamon on the W2 of the edge bevel. Hopefully.

Attachments

Last edited: