UncleBillyKnives

Well-Known Member

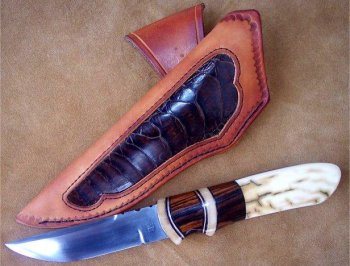

This are some of the first sheathes I have tooled. the one to the far right is one i did not finish due the the pattern moves in from the fold so it looks like it is not centered. After this one, I moved in to about 1/8" from the center line before the fold. It still comes in from the fold, but not as bad. I think it is because the fold is more rounded at the top and more flat at the bottom. Is this a common issue? On the next one I think I will start 1/8" off the center at the top and angle down to meet the center line at the bottom. Also, I will try a butterfly style sheath like Paul Long in his video to avoid the issue all together.

Also, using the swivel knife, my lines look good until i fold the leather, then the cuts look a little ragged. I have used metal blades and then got a ceramic blade. i though the ceramic blade would be smoother but it seemed to jump more. Any suggestions? the one on the left was done with a groover not a swivel knife. what looks nicer to you?

Also, using the swivel knife, my lines look good until i fold the leather, then the cuts look a little ragged. I have used metal blades and then got a ceramic blade. i though the ceramic blade would be smoother but it seemed to jump more. Any suggestions? the one on the left was done with a groover not a swivel knife. what looks nicer to you?

Attachments

Last edited: