Cazador

Well-Known Member

I recently finished up these knives. In the Captain Obvious department, photography is not my strong suit.

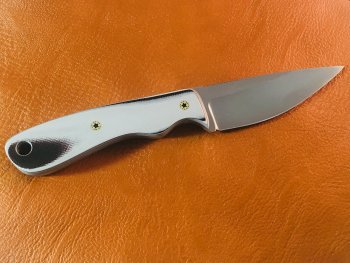

This knife is made from .156 CPM-154 steel. It has an overall length of 6 ⅞” and measures 2 ⅞” from tip to handle. The cutting edge is right around 2 ⅝”. The blade is a full flat grind. The handles are black Richlite with two mosaic pins. Not pictured, but the knife has a Kydex sheath that is set for a large Tek-Lok.

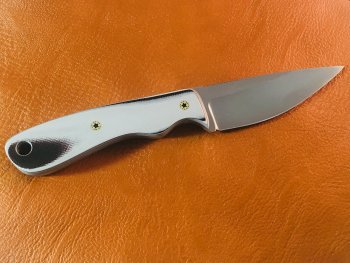

This knife is made from .156 AEB-L steel. It has an overall length of 6 ¾” and a cutting edge of 2 ¾”. The blade has a hollow grind with a 600 grit hand rubbed satin finish. The flats are finished to 400 grit. The handle is Black and Gray G10 with two mosaic pins. I still need to complete the Kydex sheath for it.

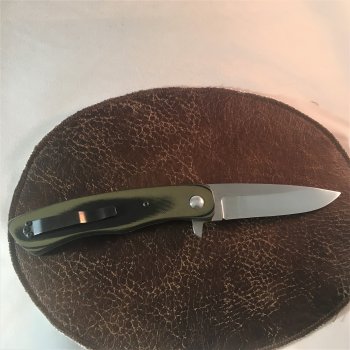

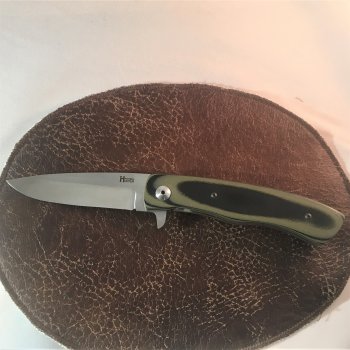

So while waiting on my steel supply to arrive I had a small piece of .138” AEB-L left over. So I decided to make a very basic liner-lock flipper. Shortly after I retired I had the opportunity to take a folder class from Jim Minnick. For those who don't know, Jim is an awesome knifemaker. I think I took the class too early into my knife making because I didn't really understand all of the intricacies of what goes into a liner lock. Anyway, this knife still needs some refinement, but all-in-all I’m pretty happy with the results. The blade is running on Nylatron washers, has good solid lock-up with no blade play. The open length of the knife is just under 8 ¾” with a cutting edge of just about 3 ⅝”. Closed the knife measures 5 ⅛”. Liners are .062” titanium with black and OD green G-10 handles.

This knife is made from .156 CPM-154 steel. It has an overall length of 6 ⅞” and measures 2 ⅞” from tip to handle. The cutting edge is right around 2 ⅝”. The blade is a full flat grind. The handles are black Richlite with two mosaic pins. Not pictured, but the knife has a Kydex sheath that is set for a large Tek-Lok.

This knife is made from .156 AEB-L steel. It has an overall length of 6 ¾” and a cutting edge of 2 ¾”. The blade has a hollow grind with a 600 grit hand rubbed satin finish. The flats are finished to 400 grit. The handle is Black and Gray G10 with two mosaic pins. I still need to complete the Kydex sheath for it.

So while waiting on my steel supply to arrive I had a small piece of .138” AEB-L left over. So I decided to make a very basic liner-lock flipper. Shortly after I retired I had the opportunity to take a folder class from Jim Minnick. For those who don't know, Jim is an awesome knifemaker. I think I took the class too early into my knife making because I didn't really understand all of the intricacies of what goes into a liner lock. Anyway, this knife still needs some refinement, but all-in-all I’m pretty happy with the results. The blade is running on Nylatron washers, has good solid lock-up with no blade play. The open length of the knife is just under 8 ¾” with a cutting edge of just about 3 ⅝”. Closed the knife measures 5 ⅛”. Liners are .062” titanium with black and OD green G-10 handles.