mrbladeblanks

Dealer - Purveyor

Dear Knife Dogs Community: I would like to introduce myself, Mark, and my business partner, Matt. We are starting an online, custom blade blank cutting service. We are calling it MrBladeBlanks.com. Our service is specifically for knife makers.

Both Matt and I are avid knife enthusiasts. I started off collecting knifes that were passed down by my father, and a few years ago I starting making knifes with simple hand tools. Matt has been collecting knives, zippos, and other cool things for the last 20 years.

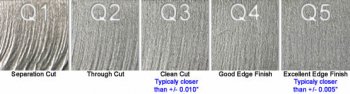

Our mission is to provide the knife making hobbyist the ability to custom design a blade in their choice of steel, and have it professionally waterjet cut and sent out as quickly as possible.

While we are in the process of starting up this business, we would like to offer our service to the Knife Dogs Community. We would like to begin by taking orders each week for a particular type and thickness of steel, and through this process we can keep prices manageable, and there will be no minimum quantity. It’s fine to order only one piece.

For example; for week 1 we will take orders and deliver blade blanks in 1095 steel 1/8” thick. Then the following week we take orders for blade blanks in 440C 3/16” thick, and so on.

For this week, we are taking orders to produce a run of custom blade blanks made with 1/8” 1095 Steel. For us to quote your blade, please email your .DXF file to mrbladeblanks@gmail.com. Also for this run there is no minimum quantity, its fine to order only one piece. We will reply to your email with the quote for your design and desired quantity.

If you don’t have a .DXF file for your design, we can create one for you for a small fee. Again if you’re interested please send an e-mail to mrbladeblanks@gmail.com. We will appreciate any feedback from you to help serve you better. Give us a try.

Both Matt and I are avid knife enthusiasts. I started off collecting knifes that were passed down by my father, and a few years ago I starting making knifes with simple hand tools. Matt has been collecting knives, zippos, and other cool things for the last 20 years.

Our mission is to provide the knife making hobbyist the ability to custom design a blade in their choice of steel, and have it professionally waterjet cut and sent out as quickly as possible.

While we are in the process of starting up this business, we would like to offer our service to the Knife Dogs Community. We would like to begin by taking orders each week for a particular type and thickness of steel, and through this process we can keep prices manageable, and there will be no minimum quantity. It’s fine to order only one piece.

For example; for week 1 we will take orders and deliver blade blanks in 1095 steel 1/8” thick. Then the following week we take orders for blade blanks in 440C 3/16” thick, and so on.

For this week, we are taking orders to produce a run of custom blade blanks made with 1/8” 1095 Steel. For us to quote your blade, please email your .DXF file to mrbladeblanks@gmail.com. Also for this run there is no minimum quantity, its fine to order only one piece. We will reply to your email with the quote for your design and desired quantity.

If you don’t have a .DXF file for your design, we can create one for you for a small fee. Again if you’re interested please send an e-mail to mrbladeblanks@gmail.com. We will appreciate any feedback from you to help serve you better. Give us a try.