I have always liked stone on knife handles. First go around with it. And the next time will be between bolters or as spacers.

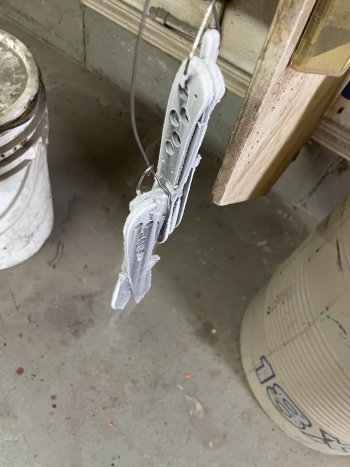

View attachment 81607

This is serpentine. It looks like there are cracks in it, but it's not. Those straight lines are the other mineral running through it. Although it might be a fracture point if hit hard enough. I tried to break them by hand and couldn't. I assembled it with epoxy and hidden pins in case of a fracture. But like I said next time the scales wont be so exposed.

View attachment 81608