You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop?

- Thread starter Justin Presson

- Start date

J. Doyle

Dealer - Purveyor

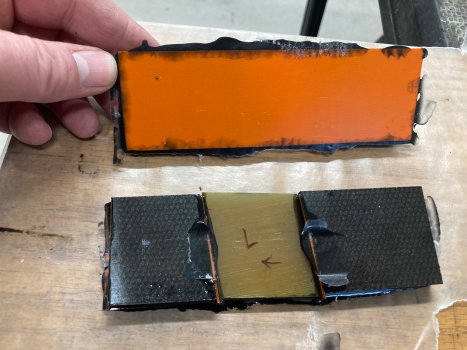

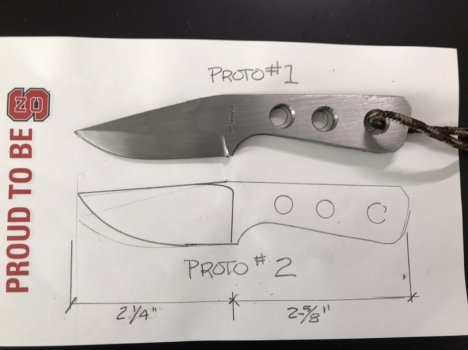

Looks pretty cool. I think it'd go from really great to outstanding if the point was raised just a bit and with a full height grind, in my unsolicited opinion.Messing around with minimalist design this morning. View attachment 82035

opaul

Well-Known Member

Thanks John ! It is a prototype I’m hoping to improve. This is from a sketch I penciled in last night. So you suggest I raise the point a bit and do a full height grind like this.Looks pretty cool. I think it'd go from really great to outstanding if the point was raised just a bit and with a full height grind, in my unsolicited opinion.

Edwardshandmadeknives

Well-Known Member

Both are nice designs. I do like the way #2 looksThanks John ! It is a prototype I’m hoping to improve. This is from a sketch I penciled in last night. So you suggest I raise the point a bit and do a full height grind like this.

View attachment 82036

J. Doyle

Dealer - Purveyor

I like that. But you wouldn't have to raise it that high even, if you didn't want to. I might try halfway between your original drawing and where it is now.Thanks John ! It is a prototype I’m hoping to improve. This is from a sketch I penciled in last night. So you suggest I raise the point a bit and do a full height grind like this.

View attachment 82036

opaul

Well-Known Member

Thanks John, I appreciate your input. As we all know - you have a keen eye for designI like that. But you wouldn't have to raise it that high even, if you didn't want to. I might try halfway between your original drawing and where it is now.

J. Doyle

Dealer - Purveyor

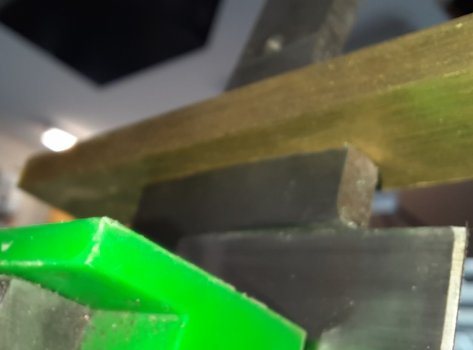

Looking good. Where's the pics of the hashbrowns? Maybe we need a "What are you cooking?" thread?This mornings labor. After a breakfast of homemade hash browns with onions. First try at trying to make exact duplicates.

View attachment 82058

CDHumiston

Well-Known Member

opaul

Well-Known Member

Looking forward to seeing the progress on this one. I love Bowie’s.Started a big Bowie knife today. 1/4" thick AEB-L Stainless steel. 9-3/4" x 2" blade. Going in the oven tomorrow...

View attachment 82059View attachment 82060

Bühlmann

Well-Known Member

I really like the coffin-esque handle profile. Your Proto #2 looks similar to an ESSEE Izula 2, which is a dang handy little blade.This mornings labor. After a breakfast of homemade hash browns with onions. First try at trying to make exact duplicates.

View attachment 82058

mike miller

KNIFE MAKER

Super glue them together to profile!This mornings labor. After a breakfast of homemade hash browns with onions. First try at trying to make exact duplicates.

View attachment 82058

opaul

Well-Known Member

I really like the coffin-esque handle profile. Your Proto #2 looks similar to an ESSEE Izula 2, which is a dang handy little blade.

Thanks I kinda like that handle detail. Any intentional resemblance is strictly by accident. I didn’t look at any knives for a design concept. The sketch just morphed into this shape. But then again there are only so many ways to draw a knife that hasn’t already been drawn.

On the other hand I am doing a custom job where the customer wants a Randall style mini. I can’t remember which well known maker it is but he actually advertises his knives as Randall duplicates.

CDHumiston

Well-Known Member

opaul

Well-Known Member

Are you going to solder the blade? Also, it might be the high resolution photos - is the ricasso finished sanded?Started getting the piece I'm using for the guard fitted today. Fit came out pretty nice!

View attachment 82064View attachment 82065

CDHumiston

Well-Known Member

Are you going to solder the blade? Also, it might be the high resolution photos - is the ricasso finished sanded?

I do plan on soldering the guard but have never done one.

There has been no sanding done yet. The blade is at 120 belt finish and has not been heat treated yet.

I just had some time today and I was working on another guard, so I did this one as well...

Edwardshandmadeknives

Well-Known Member

Stainless can be a pain to solder. I’ve found that the high temp stuff Jantz sells (I’m sure there are plenty of places to buy it) works really well. I use graphite pencil as a resist so the solder doesn’t get anywhere I don’t want it. That Bowie is looking pretty sweet.I do plan on soldering the guard but have never done one.

There has been no sanding done yet. The blade is at 120 belt finish and has not been heat treated yet.

I just had some time today and I was working on another guard, so I did this one as well...

opaul

Well-Known Member

Just saw this video. Might help some. One thing I would do differently is wrap the blade in wet paper towels or cloth. But it seems to be a well intended video on soldering knife guards. The fellow likes a wide ricasso for sure- maybe because of his soldering method.I do plan on soldering the guard but have never done one.

There has been no sanding done yet. The blade is at 120 belt finish and has not been heat treated yet.

I just had some time today and I was working on another guard, so I did this one as well...