You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop?

- Thread starter Justin Presson

- Start date

Randy Lucius

Well-Known Member

Bruce McLeish

Well-Known Member

after you are done with this set , how about a serving set for 24 ( include the butter knives and shrimp knives , too!Working on custom order. A set of ten kitchen knives in ABE-L. A chef, junior chef, utility, paring, and six steak knives. A long way to go and a lot of work before it turns into something nice.

View attachment 78645

Randy Lucius

Well-Known Member

No way my friend. This is enough work.after you are done with this set , how about a serving set for 24 ( include the butter knives and shrimp knives , too!

REK Knives

Well-Known Member

They look excellent so far! Is ht already done?Working on custom order. A set of ten kitchen knives in ABE-L. A chef, junior chef, utility, paring, and six steak knives. A long way to go and a lot of work before it turns into something nice.

View attachment 78645

Randy Lucius

Well-Known Member

Not yet. They are ready to heat treat and I’ll be doing that this week.They look excellent so far! Is ht already done?

REK Knives

Well-Known Member

Awesome, can't wait to see them come together. Will look classyNot yet. They are ready to heat treat and I’ll be doing that this week.

Adam Pound

Well-Known Member

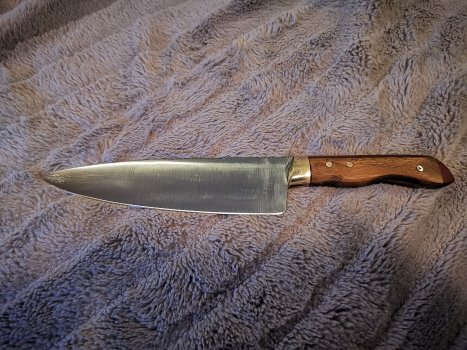

Randy, what thickness are you using for the chef's knife? I just gave my brother one (kitchen chopper, first pic) that I made using 0.125" AEBL. Not sure if that was a normal thickness to use or not for a chopper. Did another just for me in 0.093" AEBL. That works really nicely.Working on custom order. A set of ten kitchen knives in ABE-L. A chef, junior chef, utility, paring, and six steak knives. A long way to go and a lot of work before it turns into something nice.

View attachment 78645

Attachments

Randy Lucius

Well-Known Member

Hi Adam! I'm new to making kitchen knives so I'm still experimenting with thicknesses to figure out what I like. I used .074 ABEL on my first chef knife and a set of steak knives. The set of ten that I have profiled are a little thicker at .100. I heat treated three of the steak knives yesterday so we'll see how it goes.Randy, what thickness are you using for the chef's knife? I just gave my brother one (kitchen chopper, first pic) that I made using 0.125" AEBL. Not sure if that was a normal thickness to use or not for a chopper. Did another just for me in 0.093" AEBL. That works really nicely.

First chef.

Steak knives.

Randy Lucius

Well-Known Member

That's really nice! I've used scrap bits of Damascus to make jewelry and the ladies in the family love them.

Worked on these 2! Need to thin out the chefs knife a touch more behind the edge. Chopper has been a test piece (first 5160 blade). I like the handle shape and it chopped well, but I had originally done a swedge in it and it had more of a saber grind, but the tip was super fat, so I reground it thinner at the tip and it lost most of the swedge. I will probably do a full flat grind on it and may remove the harpoon to remove the remnants of the swedge. I did a flat grind, then convexed it a bit on a felt platen and then did a slack belt edge and polished it with a cloth belt and compound. I was able to cut 5/8" tree branches pretty easily with it yesterday with 1 slice; they were hanging low and hit my head when I mowed the yard, so I did some pruning.

Randy Lucius

Well-Known Member

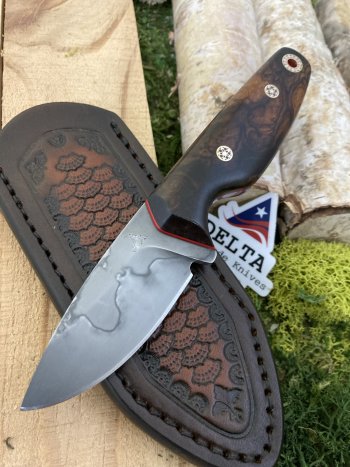

Delta Handmade Knives

Well-Known Member

REK Knives

Well-Known Member

Top one is my favorite, so classy and the red really pops... Great job on all though!Here are a few I have made lately that have gone out into the world.

Hope everyone has a great weekend!

View attachment 78671View attachment 78672View attachment 78673View attachment 78675View attachment 78676View attachment 78677

Delta Handmade Knives

Well-Known Member

Thank you!Top one is my favorite, so classy and the red really pops... Great job on all though!

Adam Pound

Well-Known Member

Stang Bladeworks

KNIFE MAKER

scott.livesey

Dealer - Purveyor

No knife today. working on 350 rpm disc grinder for finishing. using 1720 rpm 3/4 hp 110v motor and 5::1 gear reducer. had both left over from other projects. already have disc grinders with VFD and DC power. thought a plug in anywhere might be handy. also my VFD powered one does not like going this slow; it would be about 12Hz. once you get finer than 400 grit, disc life is short at high rpm.

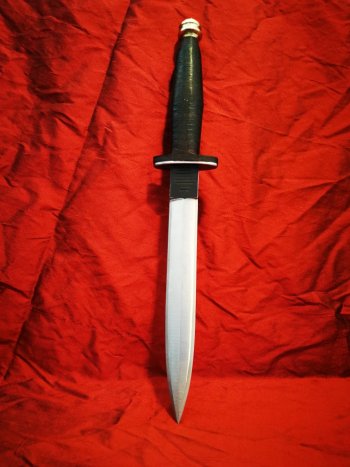

Redid the blade grind on the chopper to remove the harpoon and remnants of the swedge and to give it more of a distal taper, bring the main grind up higher on the blade, thinned out behind the edge, acid etched and made the sheath.

Got one of a set of 5 steak knives (premade blanks) with Purple/Pink Camo TJ Lam handles done to see how the block came out. It's the same order as the purple/orange/black camo TJ Lam damascus chef knife, so they will have some colorful knives in the kitchen!

Got one of a set of 5 steak knives (premade blanks) with Purple/Pink Camo TJ Lam handles done to see how the block came out. It's the same order as the purple/orange/black camo TJ Lam damascus chef knife, so they will have some colorful knives in the kitchen!

Smallshop

KNIFE MAKER

Working on a pair of knives that someone ordered as a wedding gift. The couple that will receive these run a taxidermy shop and love to hunt.

I normally do not do orders...but decided to as I want to develop this knife as more of a mid-tech product. It is a copy of Schrade's iconic Old Timer Sharpfinger. Some of the hunters up here think the Sharpfinger is the holy grail of skinning knives. (the purchaser loaned me his to copy.)

I am currently working on the scales. Will be a bolt together. I had to come up with a method of getting a stainless insert in Corian...not fun. My production models will just have checkering.(engraving tends to be a time sinkhole for me.) I changed the handle shape as the original Sharpfinger is fairly uncomfortable in your palm...

Blades will be A-2 toolsteel...

(sorry for the image quality...when I finish the pair I will take better pics and post them...)

I normally do not do orders...but decided to as I want to develop this knife as more of a mid-tech product. It is a copy of Schrade's iconic Old Timer Sharpfinger. Some of the hunters up here think the Sharpfinger is the holy grail of skinning knives. (the purchaser loaned me his to copy.)

I am currently working on the scales. Will be a bolt together. I had to come up with a method of getting a stainless insert in Corian...not fun. My production models will just have checkering.(engraving tends to be a time sinkhole for me.) I changed the handle shape as the original Sharpfinger is fairly uncomfortable in your palm...

Blades will be A-2 toolsteel...

(sorry for the image quality...when I finish the pair I will take better pics and post them...)