You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop?

- Thread starter Justin Presson

- Start date

tkroenlein

Well-Known Member

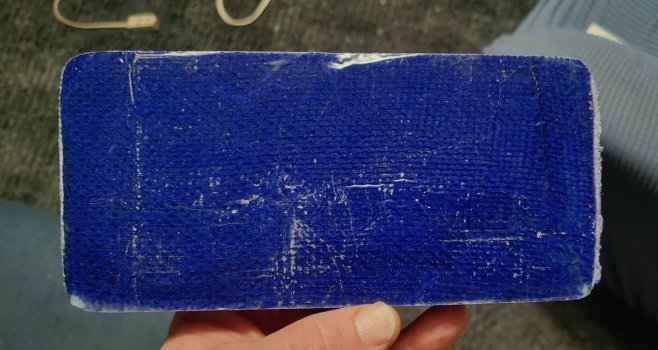

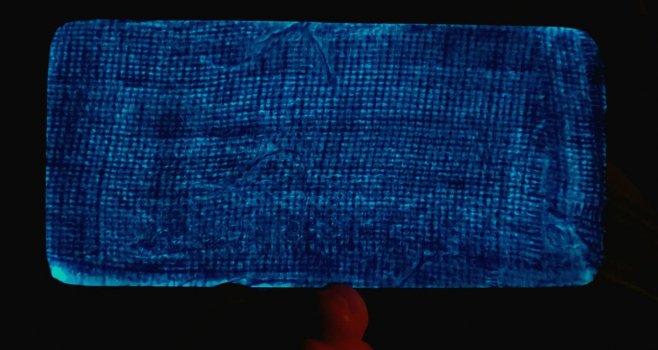

Ooooo I like that....Blue burlap with aqua glow in the dark pigment. Less pressure is the key to solid burlap it looks like!

Randy Lucius

Well-Known Member

Owl

Gold Membership

I like the profile....should make a good camp knife.

What are the holes for?

scherf68

Well-Known Member

Holes just for looks, it was boring so this popped in my head.I like the profile....should make a good camp knife.

What are the holes for?

Jesse Latham

Well-Known Member

They might make it a pain to clean. I'd probably think about filling them with brass or something. Other than that it's something I've been thinking about making.Holes just for looks

Eric Brinkerhoff

Active Member

Johan Nel

Well-Known Member

I finished this knife. I found out just how difficult it is to etch 15N20. Due to it's high nickel content, the photo positive technique does not work well for etching your logo. It took multiple failures and a final etch period of over an hour to get a decent etch. Then the logo happened to be ever so slightly skew....

This knife is a prototype, so now on to testing it.

This knife is a prototype, so now on to testing it.

Attachments

Johan Nel

Well-Known Member

Next up is this 'knife'.

It's a bit tongue in the cheek and meant as a knife to be used on the barbecue (braai). It is one of two pieces of an old sheep shear. The two pieces had separated and is quite old and well used. Not the best material for a full fledged knife, but it takes a good edge and works well for its intended purpose. It is also an interesting conversation piece.

I need to attach one of those palm tree blocks for the handle.

It's a bit tongue in the cheek and meant as a knife to be used on the barbecue (braai). It is one of two pieces of an old sheep shear. The two pieces had separated and is quite old and well used. Not the best material for a full fledged knife, but it takes a good edge and works well for its intended purpose. It is also an interesting conversation piece.

I need to attach one of those palm tree blocks for the handle.

Attachments

Last edited:

Eric Brinkerhoff

Active Member

Smallshop

KNIFE MAKER

That is a lovely knife!I finished this knife. I found out just how difficult it is to etch 15N20. Due to it's high nickel content, the photo positive technique does not work well for etching your logo. It took multiple failures and a final etch period of over an hour to get a decent etch. Then the logo happened to be ever so slightly skew....

This knife is a prototype, so now on to testing it.

tkroenlein

Well-Known Member

So I found out that I must be living right today.

I had the female half of a corby bolt sand through. It was drilled a bit extra deep and I set it a bit shallow. So it popped through a hole. If I ever thought this was gonna work, I woulda took pics of the hole process. Short version is, I was able to drill that bad boy out, drop the counter bore back into it a bit deeper, and put in a new one. I figure the Good Lord threw me a bone cuz I've been a bit behind on the book.

I had the female half of a corby bolt sand through. It was drilled a bit extra deep and I set it a bit shallow. So it popped through a hole. If I ever thought this was gonna work, I woulda took pics of the hole process. Short version is, I was able to drill that bad boy out, drop the counter bore back into it a bit deeper, and put in a new one. I figure the Good Lord threw me a bone cuz I've been a bit behind on the book.

Stang Bladeworks

KNIFE MAKER

Quick shop update. Let me know what you think.

Randy Lucius

Well-Known Member

I see Opaul hasn't responded to your question about the steep roof pitch. While I'm not sure about Opaul's reasoning, here on the Gulf Coast houses have a steep pitch for hurricane winds. A low angle roof acts like an airplane wing with the high wind flowing over the top causes a low pressure on top of roof, causing a lot of lift on the shingles. A steep pitch has the wind actually pressing down on the shingles helping prevent shingles from blowing off.Tell us more about the design of that shop, Opaul. I see you live in North Carolina, so I'm wondering why the steep pitch on the roof. I would expect that in heavy snow areas, but not so much down your way. Having seen your knives and your posts, I'm sure a lot of thought went into the design. Love the idea of a sizable cistern for the house.