J S Machine

Well-Known Member

--Finished grinder video added

I've had Solidworks on my work PC for a while now, and finally got some time to try to learn it. I've been at it for about a 3 weeks now, and I finally started getting the hang of it. There are still some things I can't do yet, but I'll figure them out eventually. I've been on a hiatus from making knives while I've tried to figure out this stuff lol. Since I got my new mill I have been busting my rear trying to fab up parts for this contraption.

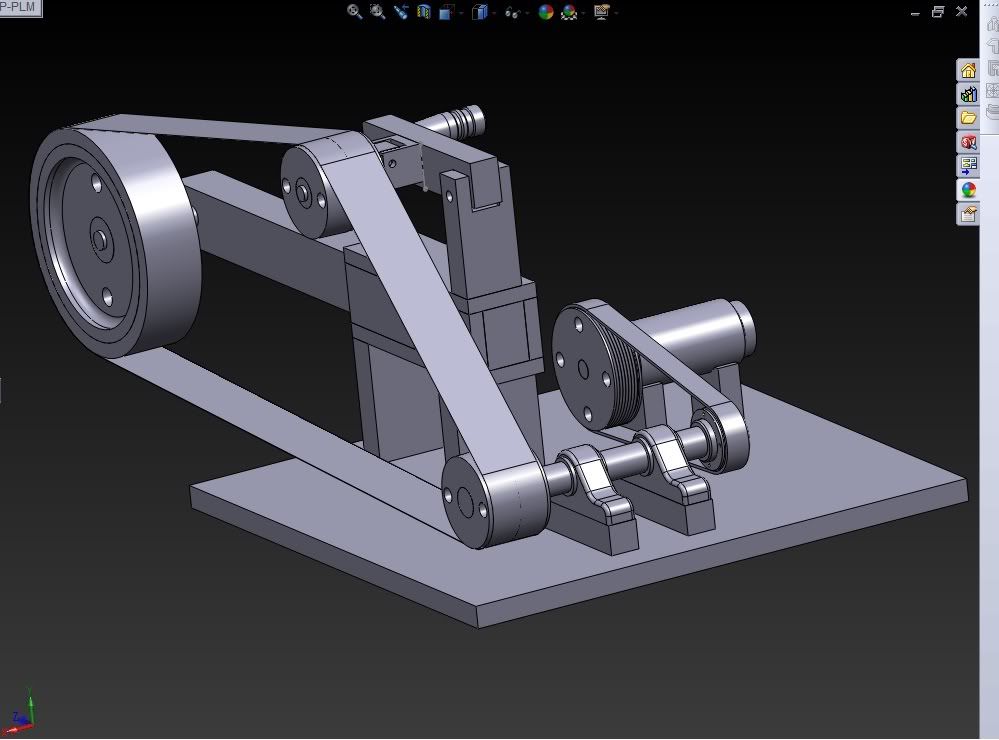

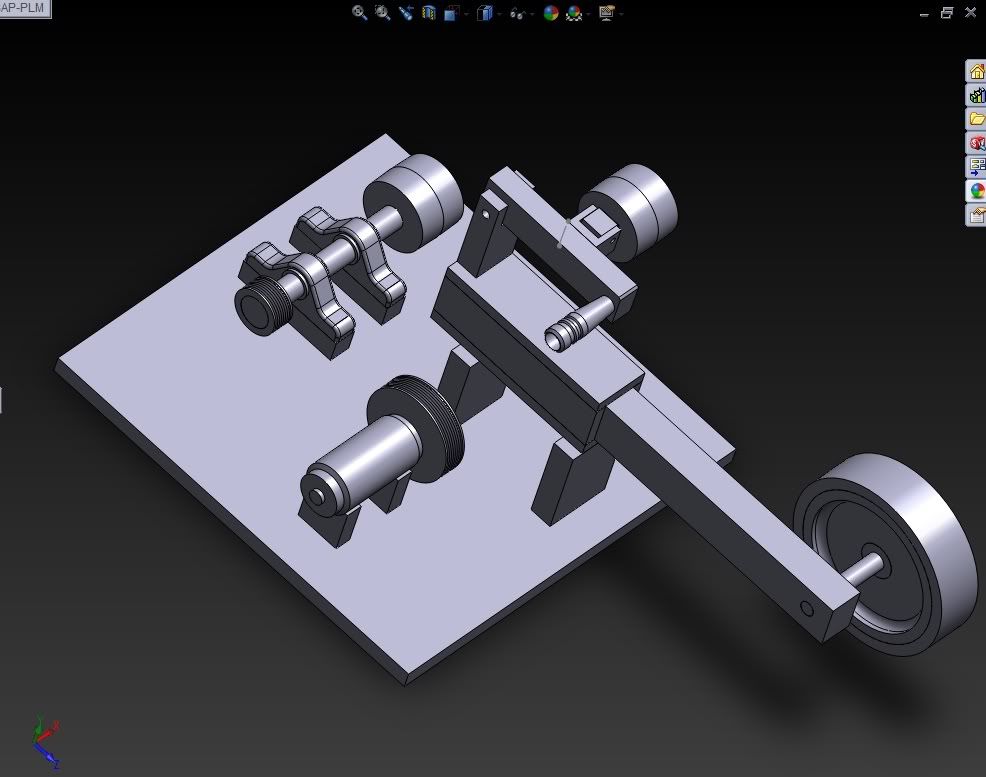

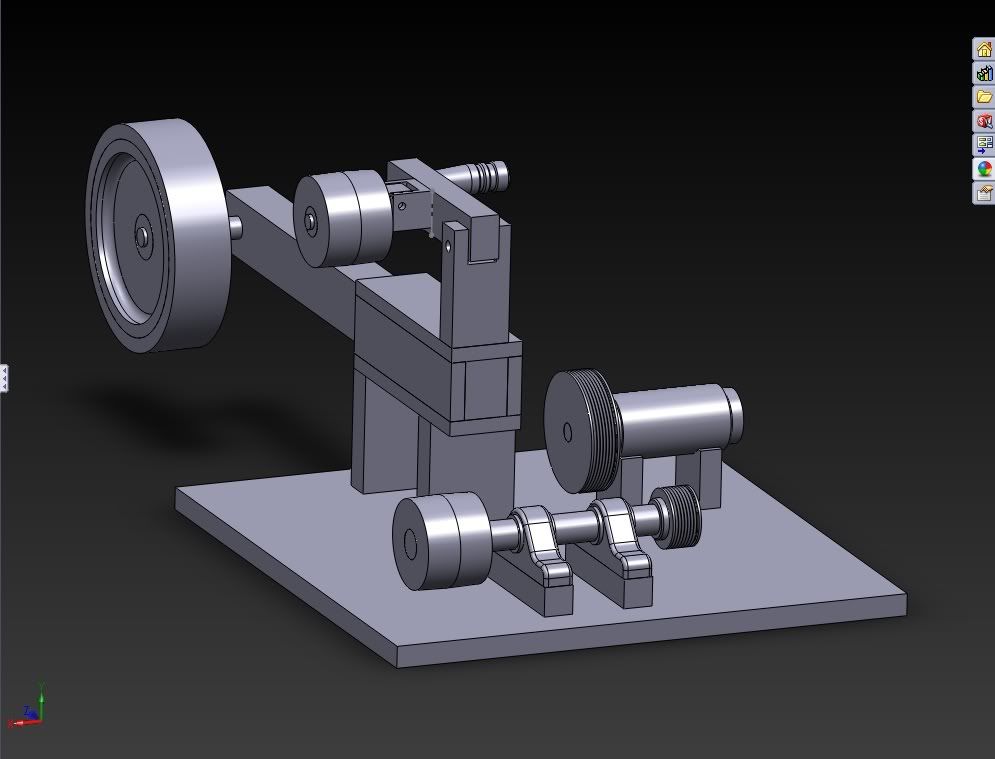

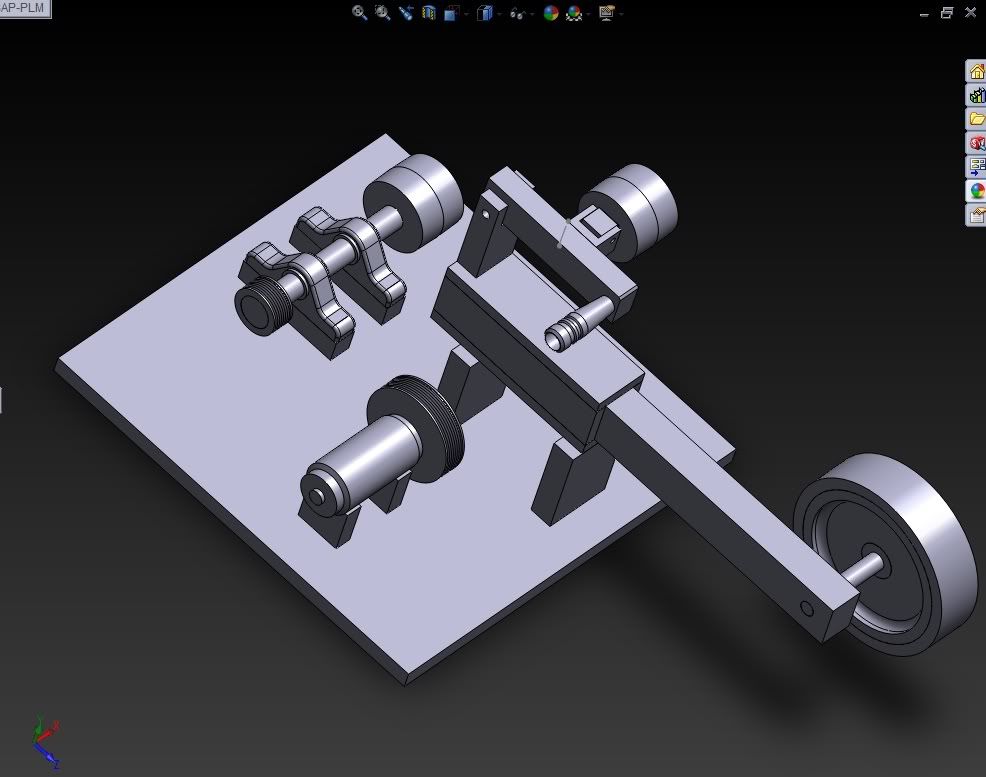

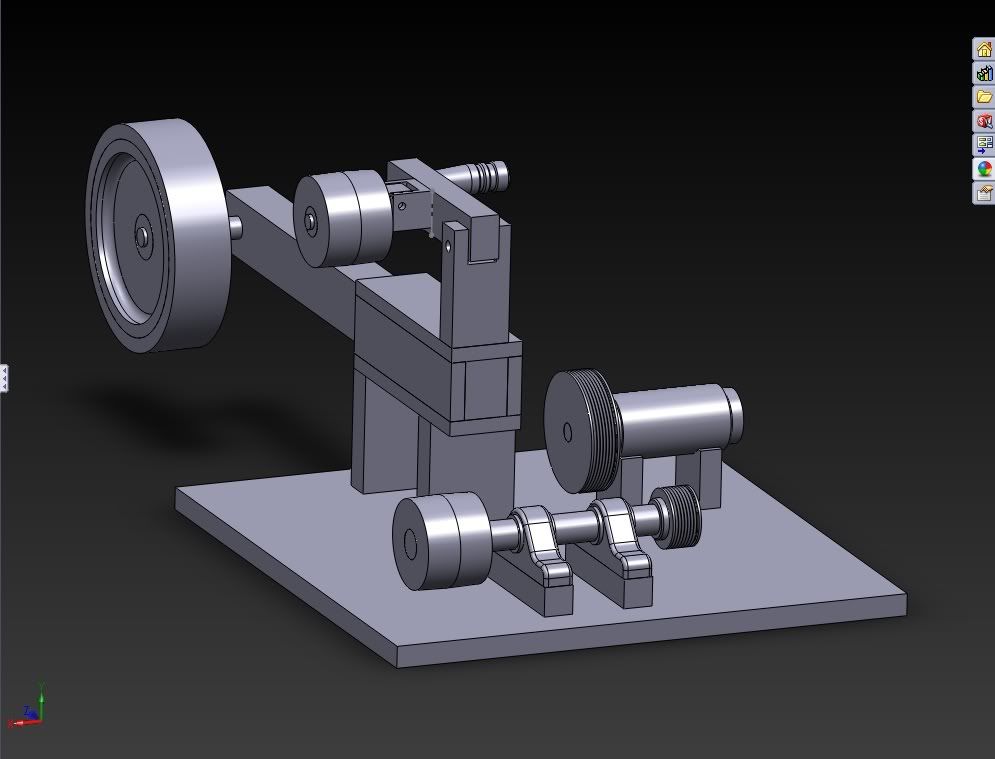

This is a grinder I am trying to build. I bought a bader contact wheel from a member here, and it will use a treadmill motor and control for power. It is of course a 2 x 72 setup, and as you can probably tell looks very similar to a KMG. Not trying to take their design, just trying to come up with something that will work. I am trying to build the thing out of old scrap pieces I have laying around here and there, so it won't look exactly like what I have here, but this gives me a good idea of what I have to deal with and how to approach it. It is actually a simple design, but there is more to it than you think. It has been a fun project and I look forward to getting it finished so I can use it.

I had previously done some work in the 3D side of AutoCAD, but it is much harder to use than Solidworks. Solidworks is a breeze. Solidworks is basically a 3D modeling program that lets you create just about anything in the virtual sense. It is a very cool program.

This is what I have so far, which is about 4 days of drawing:

There are still some things I am trying to learn, which I will update the thread with. First of all, I'd like to be able to model the serations into the contact wheel. Also, I would like to be able to actually wrap a drive belt and an abrasive belt on the pulleys. When this is all figured out, the machine will actually function (pulleys will roll, belts will track). You can create a motion study and see how it works. Very neat stuff that I hope to learn soon.

The only parts I can think of off the top of my head that are missing are the spring and it's associated mounts that go in between what I call the idler wheel arm and the capture box for the boom. There are alot of fasteners missing as well. You don't necessarily have to draw these, but it is good practice. Once I ge the hang of it, just imagine the knives that could be modeled. I can't wait

I've had Solidworks on my work PC for a while now, and finally got some time to try to learn it. I've been at it for about a 3 weeks now, and I finally started getting the hang of it. There are still some things I can't do yet, but I'll figure them out eventually. I've been on a hiatus from making knives while I've tried to figure out this stuff lol. Since I got my new mill I have been busting my rear trying to fab up parts for this contraption.

This is a grinder I am trying to build. I bought a bader contact wheel from a member here, and it will use a treadmill motor and control for power. It is of course a 2 x 72 setup, and as you can probably tell looks very similar to a KMG. Not trying to take their design, just trying to come up with something that will work. I am trying to build the thing out of old scrap pieces I have laying around here and there, so it won't look exactly like what I have here, but this gives me a good idea of what I have to deal with and how to approach it. It is actually a simple design, but there is more to it than you think. It has been a fun project and I look forward to getting it finished so I can use it.

I had previously done some work in the 3D side of AutoCAD, but it is much harder to use than Solidworks. Solidworks is a breeze. Solidworks is basically a 3D modeling program that lets you create just about anything in the virtual sense. It is a very cool program.

This is what I have so far, which is about 4 days of drawing:

There are still some things I am trying to learn, which I will update the thread with. First of all, I'd like to be able to model the serations into the contact wheel. Also, I would like to be able to actually wrap a drive belt and an abrasive belt on the pulleys. When this is all figured out, the machine will actually function (pulleys will roll, belts will track). You can create a motion study and see how it works. Very neat stuff that I hope to learn soon.

The only parts I can think of off the top of my head that are missing are the spring and it's associated mounts that go in between what I call the idler wheel arm and the capture box for the boom. There are alot of fasteners missing as well. You don't necessarily have to draw these, but it is good practice. Once I ge the hang of it, just imagine the knives that could be modeled. I can't wait

Last edited: