Walker, Terzuola, and others have really pushed the triangle aspect.

An equilateral triangle being a very strong geometric shape.

This makes a lot of sense on first, second, and third look, but if you really start thinking about it, picturing the forces, and even drawing out examples, it doesn't hold up.

The triangle itself doesn't matter.

How, and where the points of contact are at, does matter.

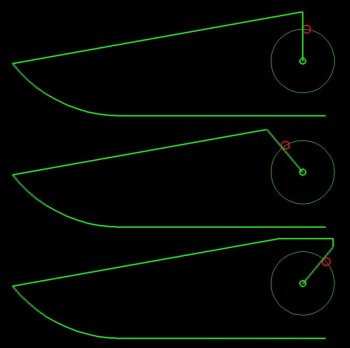

Here's another sketch demonstrating a stop pin.

The circle in all 3 is the same. It's the distance between centers of the pivot and stop pin. The only thing changing is the rotation of that pin.

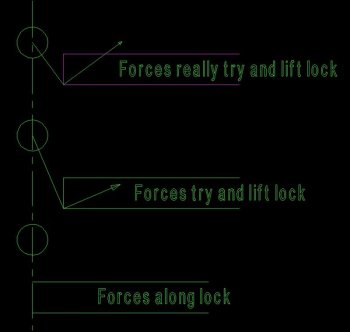

The force on a stop pin, with the knife open, is applied when there is pressure on the cutting edge, or from the lockbar.

Put pressure on the spine, and you are removing pressure from the stop pin, and putting it on the lock bar.

The only time there is pressure on both, is when the knife is static. Just open and sitting there. This is the main reason why the triangle doesn't mean anything.

Sure it's a very strong geometric shape, but in a knife, there is never any real force applied to all 3 points, which is what makes a triangle strong.

While cutting, pressure is removed from the lock, and put on the stop pin.

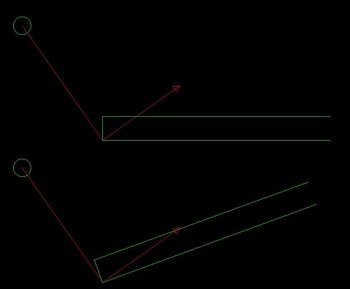

Any of these 3 stop pin positions will be equally strong, providing the material the pin is in has the strength to not deform.

It's a Class 1 lever and fulcrum, and the applied force and load is the same in all 3.

They look dramatically different, but in reality, the forces are all the same.

Providing of course that the contact point is on a line tangent to the stop pin and through the center of the pivot.

Change that point of contact, and a ton of other variables are introduced.

View attachment 25696

A stop pin in any of these positions, or anywhere in that arc will be equally strong in this design.

So, you just have to work out where it will work best in any given knife design.

The further away from the pivot the better.

But where it's at, at least mechanically, means very little, providing you have your points of contact correct.