Calvin Robinson

Moderator Christian Forum

That tough customer is me! :biggrin:

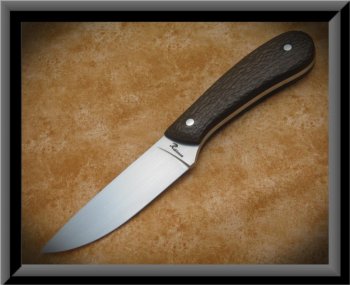

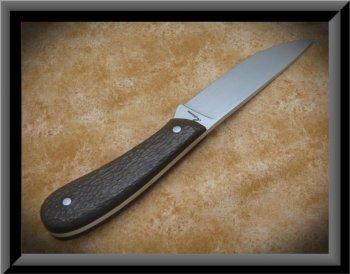

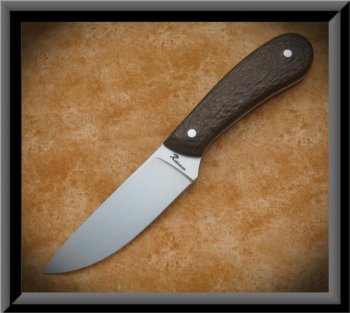

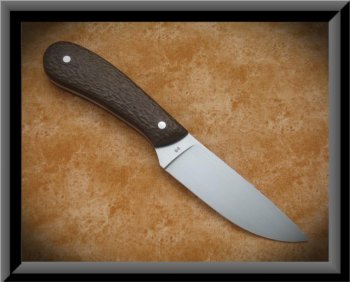

This is my Big Brother skinner model, I'll skin and quarter six or eight deer a year with it. I flat ground the 4" D-2 blade and hand jigged the chocolate paper micarta. Next order of business, a leather sheath.

This is my Big Brother skinner model, I'll skin and quarter six or eight deer a year with it. I flat ground the 4" D-2 blade and hand jigged the chocolate paper micarta. Next order of business, a leather sheath.