Mr.Svinarich

Well-Known Member

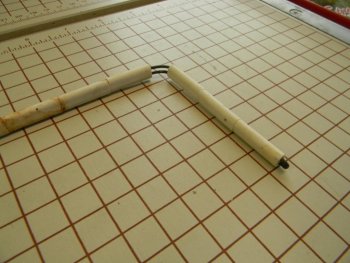

Yesterday I received my first oven, an Evenheat artisan 688. During packaging someone put a blade fixture inside the chamber. upon its adventures through the states with UPS the blade fixture rattled, pins went everywhere and the surface of the chamber was damaged. The thermocouple at the back ( which is encased in ceramic) had the ceramic snapped, not off, but in half. There is also a very prominent chip on the door of the apparatus next to the corner; but perhaps most importantly, 2 very deep cracks in the ceramic of the chamber. The cracks ( at least one) reaches the outside.

How much will these problems (thermocouple, chip, and cracks) affect the performance of the unit?

If there are problems can they be fixed?

How much will these problems (thermocouple, chip, and cracks) affect the performance of the unit?

If there are problems can they be fixed?