Hello!

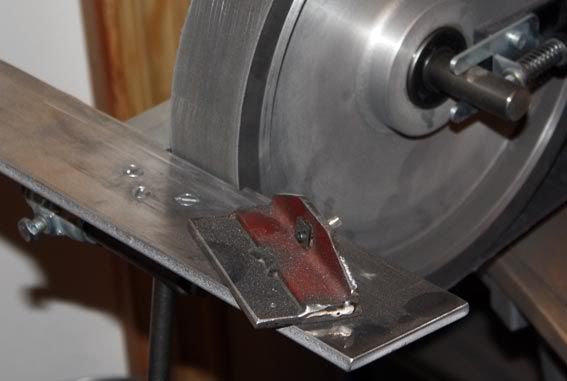

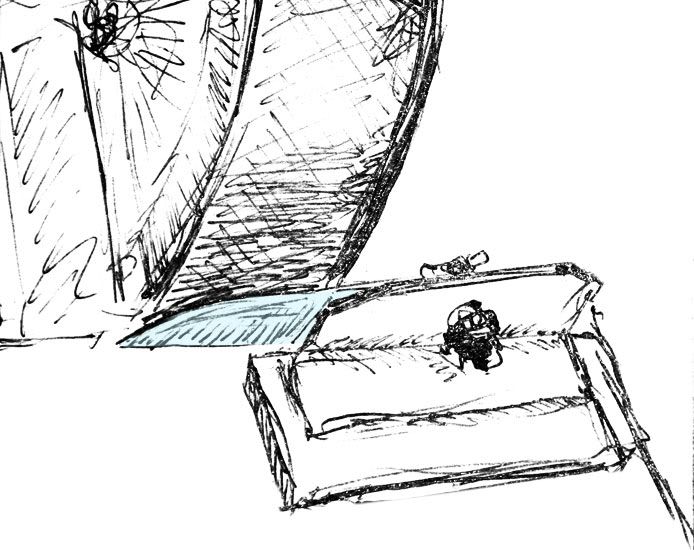

Can anybody please try to explain what I'm doing wrong here.

Sees like this always is the start of my grinding - the rest

is just trying to correct my error. Obviosly I'm trying to to make a

straight line but this seem almost impossible.

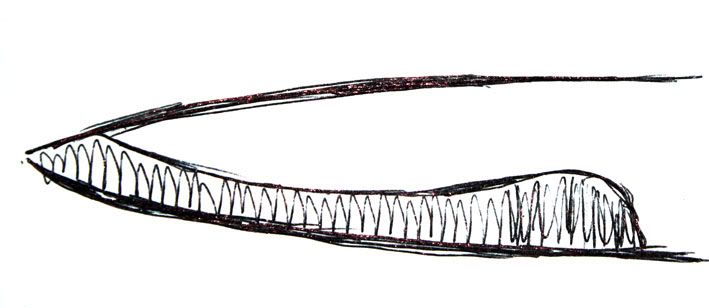

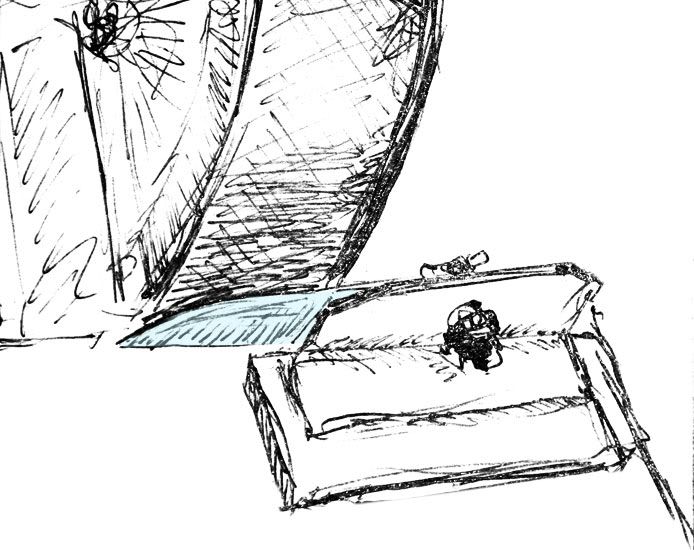

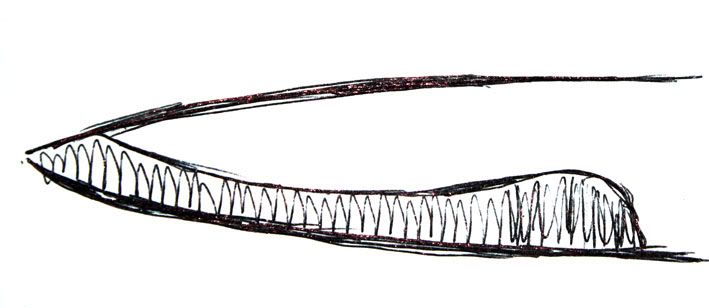

Couple of drawings here - hope they explain what's going on.

Regards

Rasmus

Can anybody please try to explain what I'm doing wrong here.

Sees like this always is the start of my grinding - the rest

is just trying to correct my error. Obviosly I'm trying to to make a

straight line but this seem almost impossible.

Couple of drawings here - hope they explain what's going on.

Regards

Rasmus