You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

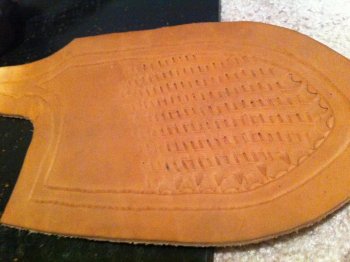

Botched sheath

- Thread starter theWeatherman

- Start date

TacticallySharp

KNIFE MAKER

I had that happen when i started. Let the leather dry more before stamping it. Back to nearly It's dry color.

Mark Behnke

Well-Known Member

Is that a craftool 501 stamp?

I'm new to stamping and could not make that stamp look good, maybe it's just me.

The fading is as said above, too wet.

Any recommendations for an intermediate basket weave stamp?

Thanks Mark

I'm new to stamping and could not make that stamp look good, maybe it's just me.

The fading is as said above, too wet.

Any recommendations for an intermediate basket weave stamp?

Thanks Mark

Paul Long

Well-Known Member

Belly leather??? That is nearly always a problem with stamping or carving. Very hard to get soft belly leather to case (Wet) evenly. it will nearly always stretch in odd direction when stamped with geometric pattern tools. Basket weave seems easy but it is one of the most demanding tools in your rack. There is a section on basket weave stamping in the new third DVD mentioned below.

Paul

Paul

Attachments

theWeatherman

Well-Known Member

Belly leather??? That is nearly always a problem with stamping or carving. Very hard to get soft belly leather to case (Wet) evenly. it will nearly always stretch in odd direction when stamped with geometric pattern tools. Basket weave seems easy but it is one of the most demanding tools in your rack. There is a section on basket weave stamping in the new third DVD mentioned below.

Paul

I went to Tandy and I asked for some 6-7oz leather for sheaths and that is what they directed me to. Paul, do you have any suggestions that I could get at Tandy?

Paul Long

Well-Known Member

A couple of facts first. The cheapest leather you can find will turn out to be the most expensive leather you ever use. Until you gain some personal experience in selecting your leather you will be at the mercy of one of the Tandy employees. Always request USA tanned leather and then check the back side of the leather (flesh side) for a nice tight , firm "hand", no soft mushy loose fiber stuff. If you are not lining your sheaths you might step up to 7/8 or even 9/10 weight leather. It will stamp much better and be overall superior for your style sheaths. With the firm hand and heavier weights it will be less likely to stretch when tooling, You can also prevent stretching to a great degree by using clear packing tape on the flesh side and then remove it when the job is done. This would help it hold its shape.

And now to my first point. I don't care how much you saved on the first leather, it represents a total dollar loss now, plus your time and effort that went into it. I do think the light weight of the leather was at least an equal contributing factor.

Paul

And now to my first point. I don't care how much you saved on the first leather, it represents a total dollar loss now, plus your time and effort that went into it. I do think the light weight of the leather was at least an equal contributing factor.

Paul

TacticallySharp

KNIFE MAKER

Buy single shoulders and get them from one of the leather houses on the internet. They make nice sheaths. Try some horse hide for something different.

Doug Lester

Well-Known Member

Some good advice here already but let me add a couple of things. One is that it looks like you were using a light weight leather. Maybe 4-5 oz from the appearance. As stated a heavier leather will stamp better. If you want an exercise in futility, try stamping 2 oz leather (don't ask how I know:shush . Also make sure that you are using vegetable tanned leather if you haven't been, couldn't really tell from the picture. Chrome tanned leather won't take a stamp and I don't imagine oil tanned would do any better. Both will lead to corrosion of the blade.

. Also make sure that you are using vegetable tanned leather if you haven't been, couldn't really tell from the picture. Chrome tanned leather won't take a stamp and I don't imagine oil tanned would do any better. Both will lead to corrosion of the blade.

On the positive side, your layout looks good and your stamping was more even than a lot of beginners can do, me definitely included. It's pretty easy to get out of alignment with a basket weave stamp. I've seen pouch sheaths laid out with the belt strap integral to the body but I like to cut my strap separately and sew it onto the pouch. Whether you want to tool the back side of the pouch and under where the belt strap will be sewn is up to you. Some like to make a border right where the leather will fold over and not take the pattern past there on the philosophy that the back isn't seen or the irregular surface of the tooling will promote wear as the sheath rubs up against clothing.

Get a good video on sheath making to see how to lay out your pattern. Paul's have a good reputation. I have Chuck Burrow's. You will pick up a lot more tips from them than you will ever be able to pick up from these threads.

Doug

On the positive side, your layout looks good and your stamping was more even than a lot of beginners can do, me definitely included. It's pretty easy to get out of alignment with a basket weave stamp. I've seen pouch sheaths laid out with the belt strap integral to the body but I like to cut my strap separately and sew it onto the pouch. Whether you want to tool the back side of the pouch and under where the belt strap will be sewn is up to you. Some like to make a border right where the leather will fold over and not take the pattern past there on the philosophy that the back isn't seen or the irregular surface of the tooling will promote wear as the sheath rubs up against clothing.

Get a good video on sheath making to see how to lay out your pattern. Paul's have a good reputation. I have Chuck Burrow's. You will pick up a lot more tips from them than you will ever be able to pick up from these threads.

Doug

theWeatherman

Well-Known Member

Doug - I am using 6-7oz leather in the picture.

Do the videos tell you about the different type of leather you are suppose to use?

I really don't know anything about leather and just took the word of the guy at Tandy, and I am regretting it, it seems. So what type of leather, oz and name should I be using if I did not want to tool and then if I did want to tool the leather?

Paul or TacticallySharp, could you point me in the right direction of a type of leather, ( a link or something really really specific?)

I will have to get a hold of either Paul Long's or Chuck Burrow's video. Just another learning experience I guess. I feel like if I make the knife that I should be able to make a nice sheath as well.

Thanks for all your help guys. This set me back a notch and made me think and disappointed in my self but I have a ton of this leather left so I guess I will just have to practice and figure it out (Picture). I don't know exactly what I got from Tandy so I am attaching the pic of the tag and maybe that will tell you more about what the leather is?

Do the videos tell you about the different type of leather you are suppose to use?

I really don't know anything about leather and just took the word of the guy at Tandy, and I am regretting it, it seems. So what type of leather, oz and name should I be using if I did not want to tool and then if I did want to tool the leather?

Paul or TacticallySharp, could you point me in the right direction of a type of leather, ( a link or something really really specific?)

I will have to get a hold of either Paul Long's or Chuck Burrow's video. Just another learning experience I guess. I feel like if I make the knife that I should be able to make a nice sheath as well.

Thanks for all your help guys. This set me back a notch and made me think and disappointed in my self but I have a ton of this leather left so I guess I will just have to practice and figure it out (Picture). I don't know exactly what I got from Tandy so I am attaching the pic of the tag and maybe that will tell you more about what the leather is?

leatherman

Sheath Forum Moderator

Looks like a half shoulder to me, not familiar with the number though. The 02 at the end suggests that is a #2 grade and is just fine for sheath work, the weight is ok as well for pouches. If that is indeed a half shoulder you were sent in the right direction.

Your stamping suggests one of two things and I agree with everyone here, its either too wet or too dry. As you stamp the leather slowly dries and your impressions will get shallower, or if its too wet then the leather acts like a sponge and simply expands back into shape.

It just takes practice and experience to get it all down, I've got a whole bin of rejects to show that.

EDIT: I found the number on Tandy's site and it is indeed whats called either a single or half shoulder, depending on where you are. Good stuff, you didnt get messed over.

Your stamping suggests one of two things and I agree with everyone here, its either too wet or too dry. As you stamp the leather slowly dries and your impressions will get shallower, or if its too wet then the leather acts like a sponge and simply expands back into shape.

It just takes practice and experience to get it all down, I've got a whole bin of rejects to show that.

EDIT: I found the number on Tandy's site and it is indeed whats called either a single or half shoulder, depending on where you are. Good stuff, you didnt get messed over.

Last edited:

theWeatherman

Well-Known Member

I am guessing that it was too wet then. I made it as wet as I could because I was told just "wet". I didn't know it could be too wet.

Thanks!!!!!

Thanks!!!!!

Paul Long

Well-Known Member

In answer to your previous question directed to me. I use utility skirting sides from Wickett & Craig Tannery and I have it split to 7/8 oz, because I fully line each sheath with either deer skin or 2/3 oz leather. Wickett &Craig will sell as little as one side at a time, but that would still be about 5 or 6 times the quantity you bought, and would be about a $150 investment including the freight.

Dwayne did some pretty good research on what you got from Tandy and it should have performed pretty well, so probably the problem was that you got it too wet and started before it had dried out to the proper moisture content for stamping. Your photo does suggest that the flesh side is a little loose fibered, and that will change an improve in a different area of the same piece of leather. The area where you cut your sheath appears to be toward the belly, (not belly leather) the opposite end toward the spine should be much more firm hand and coupled with better casing technique will produce much better results.

Paul

Dwayne did some pretty good research on what you got from Tandy and it should have performed pretty well, so probably the problem was that you got it too wet and started before it had dried out to the proper moisture content for stamping. Your photo does suggest that the flesh side is a little loose fibered, and that will change an improve in a different area of the same piece of leather. The area where you cut your sheath appears to be toward the belly, (not belly leather) the opposite end toward the spine should be much more firm hand and coupled with better casing technique will produce much better results.

Paul

Last edited:

leatherman

Sheath Forum Moderator

Paul hit it right on the nose. The size of an entire side can be overwhelming in comparison to what you got, a single shoulder averages 6-8 square feet, a side can average 20 and larger (I found one once that was 30, what a beast)

I had heard at one time that W&C was working on doing some double shoulders? Not sure how that went.

When browsing Tandy, or The Leather Factory, its wise to dig, all the way to the bottom if needed. Look at the back and front carefully. As Paul said, you will come up with some with a "stringy" back, not good stuff. Thats whats referred to as a "soft hand" loose fibers can cause so many issues.

Look for an even, fuzzy feel to the back. The edges will probably still be stringy, but you can work those into welts and such. Watch for soft spots, hard to see but easy to feel out.

Its possible to get a nice chunk of leather from Tandy, you just have to dig for it. I'm lucky to have both a Tandy and TLF within driving distance so if one doesn't have what I need I'll simply go to the other.

I had heard at one time that W&C was working on doing some double shoulders? Not sure how that went.

When browsing Tandy, or The Leather Factory, its wise to dig, all the way to the bottom if needed. Look at the back and front carefully. As Paul said, you will come up with some with a "stringy" back, not good stuff. Thats whats referred to as a "soft hand" loose fibers can cause so many issues.

Look for an even, fuzzy feel to the back. The edges will probably still be stringy, but you can work those into welts and such. Watch for soft spots, hard to see but easy to feel out.

Its possible to get a nice chunk of leather from Tandy, you just have to dig for it. I'm lucky to have both a Tandy and TLF within driving distance so if one doesn't have what I need I'll simply go to the other.

ChuckBurrows

Well-Known Member

1) RJF Leather out of New York state sells some of the finest double shoulders around and the price is in line with W & C, Herman Oak, etc. Size averages 13 sq ft - my last one cost just under $80.00 including shipping.

2) On the other hand over the last 50+ years I have used a fair amount of Tandy's single shoulders in both 4/5 and 6/7 oz and generally the quality was good to excellent. On the other hand the section you cut out the sheath was the edge where a shoulder includes some belly leather, and that along with the leather most likely being TOO wet than thus the shallow stamping. And as Paul said basket weave is one of the most difficult stamp patterns to do right even for those of us having it done it for beaucoup years.

3) The 501 is it a new one or an older one? Is it one of the zinc ones or the plated steel ones (if zinc the number will include a Z. While I have no real gripe with Tandy or LF (who owns Tandy) there have been a ton of complaints with their newer tools not being of good quality and I have recently compared my old (most 30-40 years or older and well used) Craftsman tools to the new ones and there is a distinct difference in quality. I could go into depth why, but it would take too much time, but I understand that the powers to be at Tandy/LF have taken notice and are apparently working on bringing the quality back up. In the interim you might check out Ebay or Proleptics and look for older tools. While Bob Beard and others make very fine custom tools, they are expensive, but there are other alternatives that are much less expensive and only about double the price of the Craftsman brand.

2) On the other hand over the last 50+ years I have used a fair amount of Tandy's single shoulders in both 4/5 and 6/7 oz and generally the quality was good to excellent. On the other hand the section you cut out the sheath was the edge where a shoulder includes some belly leather, and that along with the leather most likely being TOO wet than thus the shallow stamping. And as Paul said basket weave is one of the most difficult stamp patterns to do right even for those of us having it done it for beaucoup years.

3) The 501 is it a new one or an older one? Is it one of the zinc ones or the plated steel ones (if zinc the number will include a Z. While I have no real gripe with Tandy or LF (who owns Tandy) there have been a ton of complaints with their newer tools not being of good quality and I have recently compared my old (most 30-40 years or older and well used) Craftsman tools to the new ones and there is a distinct difference in quality. I could go into depth why, but it would take too much time, but I understand that the powers to be at Tandy/LF have taken notice and are apparently working on bringing the quality back up. In the interim you might check out Ebay or Proleptics and look for older tools. While Bob Beard and others make very fine custom tools, they are expensive, but there are other alternatives that are much less expensive and only about double the price of the Craftsman brand.

Last edited:

leatherman

Sheath Forum Moderator

I'm very glad to hear that Tandy is looking to correct some of those stamps that are, for lack of a better word, substandard. I've picked up examples with casting voids. It doesn't happen often, but when it does its very aggravating.

I try to hit every estate sale that has leather craft in the header, those older tools are fantastic. And yes, its easy to tell the difference once you see those tools from the earlier time period. Sharper and clearer edges and not so much chrome plating. The castings are easily identifiable.

Going to have to look up RJF for some special projects, thanks for the heads up Chuck.

I try to hit every estate sale that has leather craft in the header, those older tools are fantastic. And yes, its easy to tell the difference once you see those tools from the earlier time period. Sharper and clearer edges and not so much chrome plating. The castings are easily identifiable.

Going to have to look up RJF for some special projects, thanks for the heads up Chuck.

Jim Coffee

Well-Known Member

all I can tell you is buy Pauls DVD's, I did and it was money WELL spent....

TacticallySharp

KNIFE MAKER

Weatherman,

Paul's dvds are a good place to start.

I get leather from both of these guys. The following is what I buy:

http://springfieldleather.com/25858/Bend,Belt,HermannOak,Sngle,8-9/

http://springfieldleather.com/29877/Horsebutt,DrumDyed,Brown,Ea/

http://www.theleatherguy.org/VEG-TA...5512-5-1-Square-Foot-Natural/ProductInfo.aspx

I use horse on some of my plain sheaths & for sheaths covered with exotic leathers such as gator, shark, or stingray.

I also spent a little more these days on my tools. I have about 200 midas stamping tools and a bunch of Barry King tools. When I started doing leather about 2 years ago I was lucky to have Luie (aka Daddy) at Daddy's Leather Supply in Miami as a mentor. I still go there for help as needed and to just hang out.

I still have my first sheath, basket mis-weave, not seemed (didn't fit) in my reminder drawer in the shop.

Just practise until you like what you do. I stamp on scrap leather to practise a couple of times a week.

Good luck, let me know if I can be of help.

Paul's dvds are a good place to start.

I get leather from both of these guys. The following is what I buy:

http://springfieldleather.com/25858/Bend,Belt,HermannOak,Sngle,8-9/

http://springfieldleather.com/29877/Horsebutt,DrumDyed,Brown,Ea/

http://www.theleatherguy.org/VEG-TA...5512-5-1-Square-Foot-Natural/ProductInfo.aspx

I use horse on some of my plain sheaths & for sheaths covered with exotic leathers such as gator, shark, or stingray.

I also spent a little more these days on my tools. I have about 200 midas stamping tools and a bunch of Barry King tools. When I started doing leather about 2 years ago I was lucky to have Luie (aka Daddy) at Daddy's Leather Supply in Miami as a mentor. I still go there for help as needed and to just hang out.

I still have my first sheath, basket mis-weave, not seemed (didn't fit) in my reminder drawer in the shop.

Just practise until you like what you do. I stamp on scrap leather to practise a couple of times a week.

Good luck, let me know if I can be of help.

Last edited:

TacticallySharp

KNIFE MAKER

Oh, I forgot use the leather you have, check YouTube for casing leather. There are several vids on subject for this. If it drys, carefully spong the remaining area lightly & carefully, continue stamping.

When I started doing leather about 2 years ago I was lucky to have Luie (aka Daddy) at Daddy's Leather Supply in Miami as a mentor. I still go there for help as needed and to just hang out.

I still have my first sheath, basket mis-weave, not seemed (didn't fit) in my reminder drawer in the shop.

Just practise until you like what you do. I stamp on scrap leather to practise a couple of times a week.

Good luck, let me know if I can be of help.

Lui is one of the absolute best to learn from!!!!! IFOLG Award winner!!! World class all the way. Next time you see him, dile el, Q-VO y practique tu mexicano, from me.