MTBob

Well-Known Member

Daniel, perhaps this is obvious, unless you've got 3 phase electric service in your shop, you'll need to 1) convert

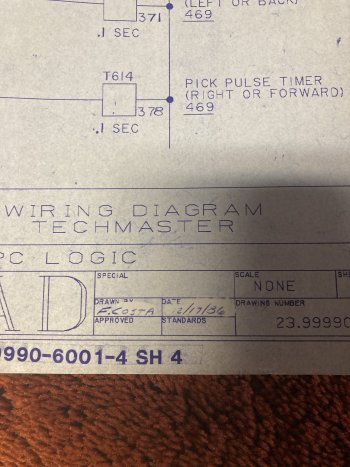

I saw on the electrical panel that the grinder appears to need 480 volt service, I'm guessing that will be 3 phase. You may want to take a hard look at whether your existing electric service can handle that machine.Here’s a video. It’s actually what I believe is a 618 techmaster I kept saying 818. Lol. If there’s anything you guys want a better look at just let me know.