You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

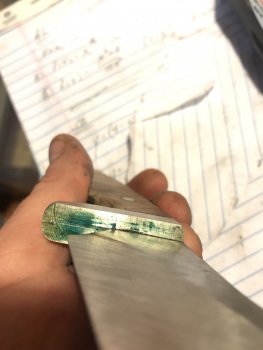

Bowie? WIP- New Pics

- Thread starter Kevin Zito

- Start date

Kevin Zito

KNIFE MAKER

Von Gruff

KNIFE MAKER

Looking good Kevin. One thing you can do to "tighten" the slot against the blade is to lightly peen the edges of the face side and if you peen the whole face it will give you another look as against a satin finished guard. Guards are often done in mild steel and left with various finishes and even fire blued on the peened surface can be a nice look if you choose a handle material and blade finish to compliment it. That is going to be a very fine looking knife when finished. Paitence and forethought will get you as good a finished knife as can be had by any means of making.

Kevin Zito

KNIFE MAKER

Wow gruff thanks for the advice... I never thought of that. The guard is nickel silver so it may work. Thank you also for the compliments!Looking good Kevin. One thing you can do to "tighten" the slot against the blade is to lightly peen the edges of the face side and if you peen the whole face it will give you another look as against a satin finished guard. Guards are often done in mild steel and left with various finishes and even fire blued on the peened surface can be a nice look if you choose a handle material and blade finish to compliment it. That is going to be a very fine looking knife when finished. Paitence and forethought will get you as good a finished knife as can be had by any means of making.

Couple more pics.

C Craft

Well-Known Member

That my friend is what I call a saddle style guard!! Not sure it that is the proper terminology but that is what I call them!!

John Wilson

Well-Known Member

I agree with Von's suggestion. Peen the top face of the guard at the edges of the slot. It will close down. Sometimes a round-faced punch just outside the slot will let you direct the metal. There are times when the metal doesn't want to cooperate, in which case you break out the 3lb Persuader and you smack the daylights out of it from the side and simply crush the slot down a bit. You will then have to re-file the slot to size (which is what you want anyway because that's the only way to get a perfect fit) and then you'll re-face the guard to get rid of the buckled metal. You'll also have to reshape the guard a little because it will not be rectangular anymore. All in a day's work. It's one of those things where you try to be delicate until delicate won't do (you decide you are wasting too much time) and then you go Cro-Magnon on it.

This reminds me of that really smart guy who said, "buy a pre-slotted guard and then use blade steel that is thicker than the slot." I forget who said that.... but anyhoo... LOL

This reminds me of that really smart guy who said, "buy a pre-slotted guard and then use blade steel that is thicker than the slot." I forget who said that.... but anyhoo... LOL

John Wilson

Well-Known Member

By the way, that gap isn't all that big, assuming the other side is the same. A very little bit of closing up combined with filling the slot with JB Weld will make that hairline crack all but disappear.

Johan Nel

Well-Known Member

Looking good! And it has crisp, clean lines too...Wow gruff thanks for the advice... I never thought of that. The guard is nickel silver so it may work. Thank you also for the compliments!

Couple more pics. View attachment 64290View attachment 64291

Kevin Zito

KNIFE MAKER

Dennis Morland

KNIFE MAKER

Going to be killer!

Kevin Zito

KNIFE MAKER

Thanks, Dennis! I’ve got my fingers crossed lol.Going to be killer!

Last edited:

Kevin Zito

KNIFE MAKER

There’s a 1/8 pin in it and it’s only 1/4 wide lol. I went slow slow! Thanks everyone for the great comments.Looks good Kev!! How are you attaching the guard??

Kevin Zito

KNIFE MAKER

Kevin Zito

KNIFE MAKER

Kevin Zito

KNIFE MAKER

Thanks! I got it from GeneK. He has beautiful wood! It’s 3DNice. I especially like your handle shape. Looks comfortable with beautiful grain, too.