Justin Presson

Well-Known Member

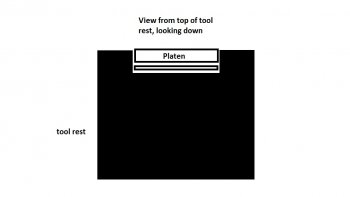

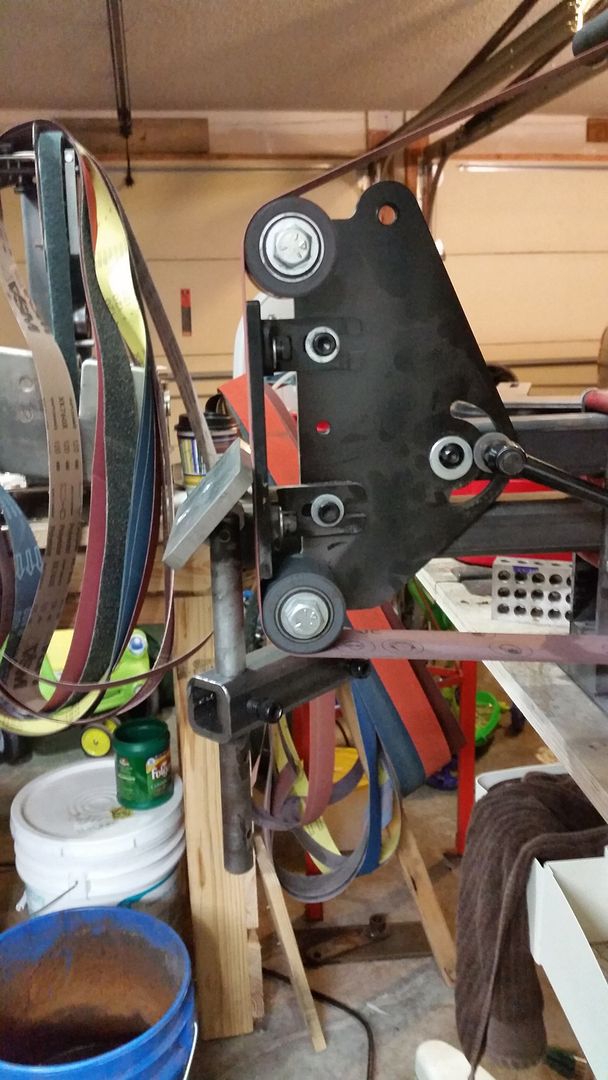

Had the day off, wohoo had some knives I needed to finish and was going to use my new 400 grit cork belt. So I proceeded to break it in with a bar of steel a few minutes in my new home buikt adjustable work rest gives way and sucked the steel bar in between the rest, my finger and the platen. Belt snapped I jerk my finger out and shut of the grinder. Glad it wasn't worse. Mad at myself for letting it happen and that a smoked the brand new belt.

The rest is not 100% done and I think guess I did not tighten it enough and had to much pressure on it.

Bonehead!!!!

So now the blades have a hand rubbed finish.

The rest is not 100% done and I think guess I did not tighten it enough and had to much pressure on it.

Bonehead!!!!

So now the blades have a hand rubbed finish.

it did...feels worse today.....lol

it did...feels worse today.....lol