First before I rant ill apologize. I have a few issues  and spend my life in a constant state of borderline suicidal.

and spend my life in a constant state of borderline suicidal.

Anyway today so depressed!

The big knife came out of heat treat well.

Today I spent 10 hours and about 100 dollars worth of wet dry paper trying to get a decent looking satin finish.

No paper left and the blade is in worse shape than when I started.

I can get a perfect mirror shine in about half an hour no problem but I dont want a mirror finish on this blade. I actually took it to a mirror finish then tried to step back a few grits to get the satin look.

I just cant get it to look uniform. It looks all streaky and unfinished.

The closest I got was at the end of the days when I wrapped the paper around a wooden dowel rather than a piece of metal I normally use.

Also somehow I warped it while hand sanding... How is that even possible... I dont even...

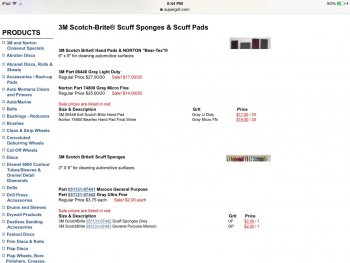

Grit progression:

150

240

320

400

600

800

1000

Anyway today so depressed!

The big knife came out of heat treat well.

Today I spent 10 hours and about 100 dollars worth of wet dry paper trying to get a decent looking satin finish.

No paper left and the blade is in worse shape than when I started.

I can get a perfect mirror shine in about half an hour no problem but I dont want a mirror finish on this blade. I actually took it to a mirror finish then tried to step back a few grits to get the satin look.

I just cant get it to look uniform. It looks all streaky and unfinished.

The closest I got was at the end of the days when I wrapped the paper around a wooden dowel rather than a piece of metal I normally use.

Also somehow I warped it while hand sanding... How is that even possible... I dont even...

Grit progression:

150

240

320

400

600

800

1000