John M Cohea

Well-Known Member

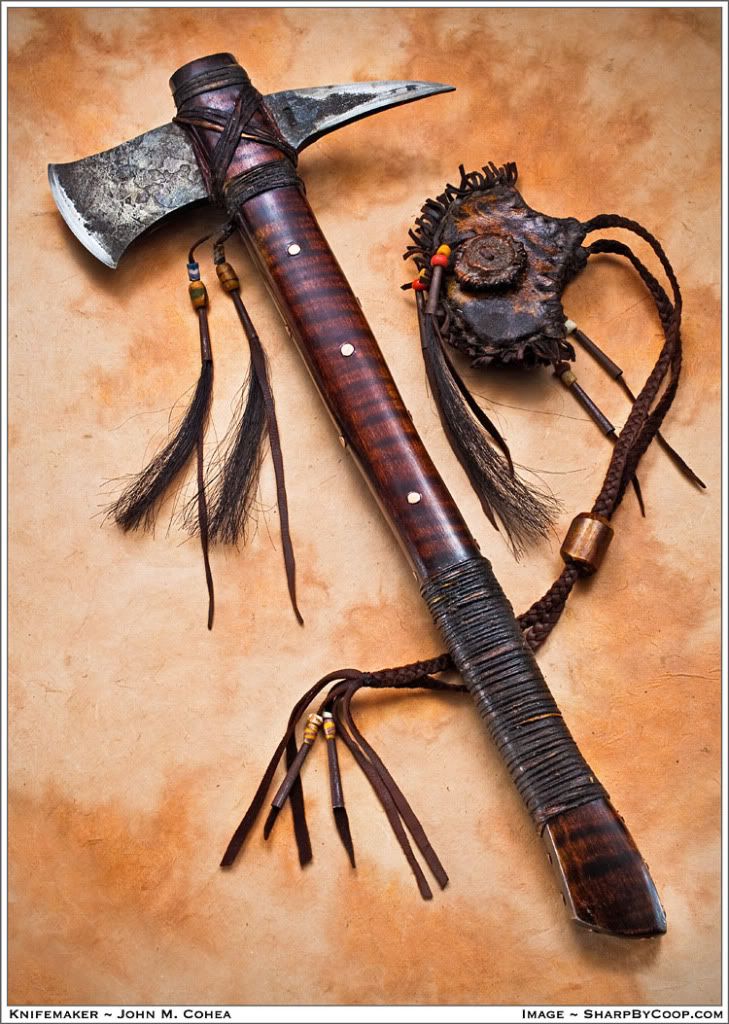

I thought I'd kick off posting pics of my work with this piece. I had this one shot by Coop at this year's Blade Show.This was the first time I have had a piece shot by a pro, and as a result it was published in this month's Knife World2thumbs, which is also a first!

Head is forged from leaf spring steel, and was left forged textured. Haft is curly maple, dyed with Fiebing's and finished in tung oil. The headcover is rawhide over veg-tan with deerskin fringe.Thanks for looking!

Head is forged from leaf spring steel, and was left forged textured. Haft is curly maple, dyed with Fiebing's and finished in tung oil. The headcover is rawhide over veg-tan with deerskin fringe.Thanks for looking!