dienekis

Well-Known Member

This is my first WIP and my first dagger so hope its informative

The steel i am using is O1 .

I start first with transfering the image to the steel.I used the spray glew to attach the print.

After using my angle grinder to cut as much steel as i could.

Then took it to the grinder and profiled it with a 40 grit belt and got this result

Before i drille the holes i attached the logo with the press but i forgot to take a picture of it.I did the main holes only so i can have an idea of the weight of it after the grinding

Now i was marking for the grind i used the tape to get the midle from the tip to the top .Did it for both sides.Hope that you understand what am i doing

After i did free grinding i got this result . I used 40 grit belt

Now its time for traditional hand rubbing before HT and also to make the lines straight when i get some time

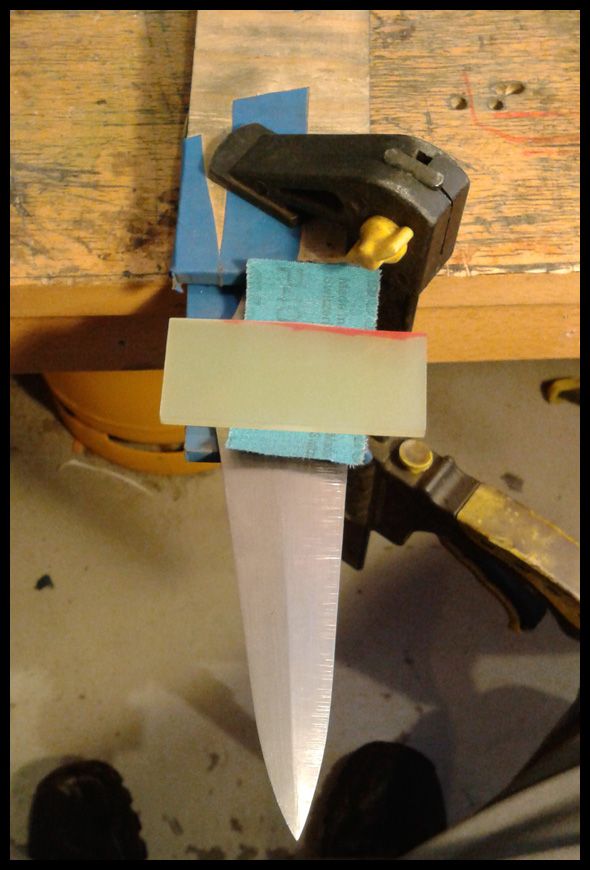

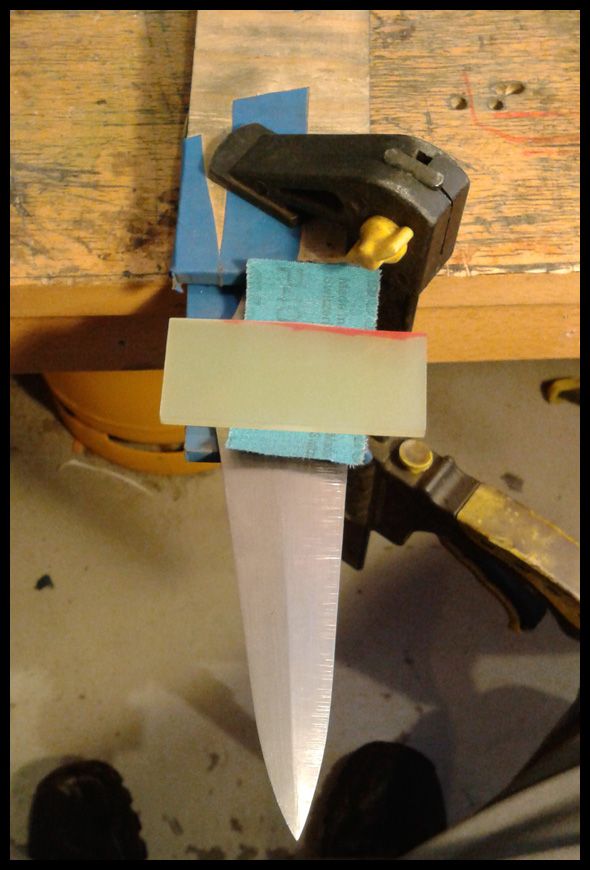

Ok handrubbing before HT .I finished till 120 grit.And the reason was i was out of sand paper and i was bored waiting .Better to finish it to 320 grit.

Much easier after + ready for HT

[video=youtube;vXfIkI9aRa0]http://www.youtube.com/watch?v=vXfIkI9aRa0[/video]

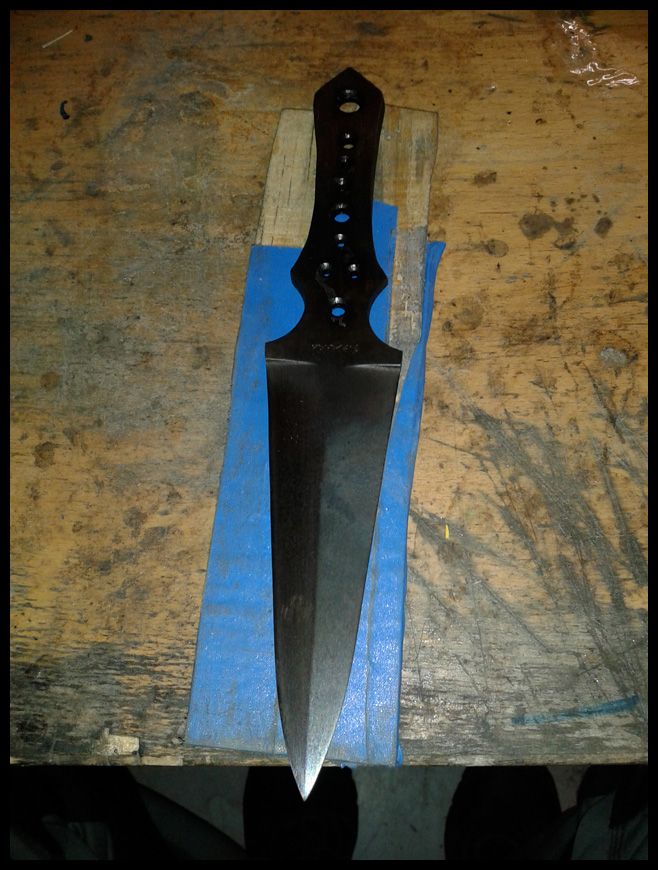

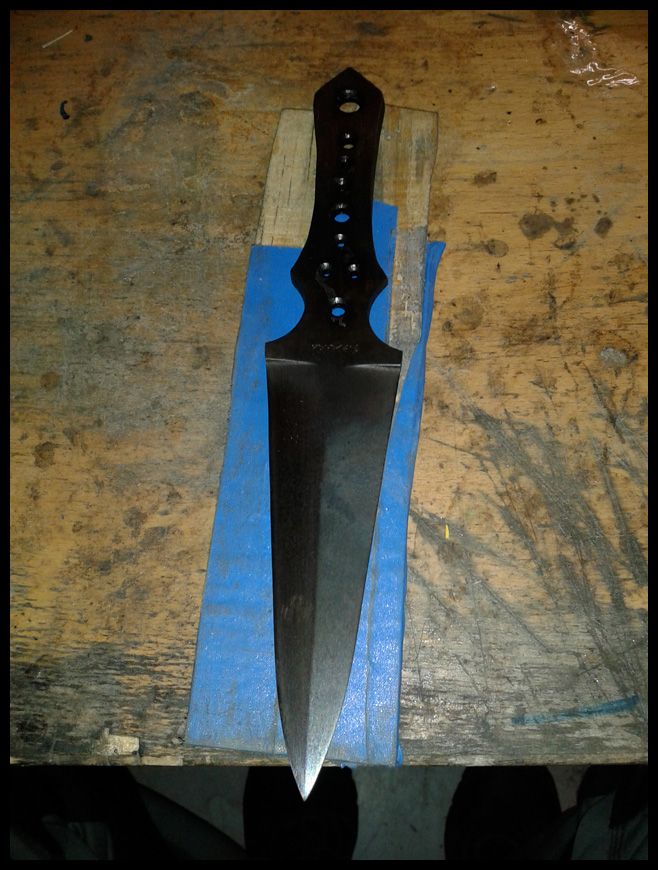

HT is done and here it is

Now hand rub again i start with 80 grit i find it easier for me and the lovely wd-40 and i finish to the point i want this is done 800 satin

After this we go to scale preparation I also sharpened the one side to test the hardening of it

Rapping with duck tape all the blade to avoid unpleasant scratches also before i tape it i usually clean it with cotton and aseton

Now i check if the scales are flat with the handle

After i am pleased i puting double side tape so i can stick the handle on mark the holes etc and profile draw the handle

AFter im done with this i take it to drill the holes,keeping the blade on the handle.

Of course i drill the corect sizw just a little bit , just to make the hole for the drill bit. Otherwise if i go all the way through ACCIDENTS might happen

As you i am using corby bolts

Also alwasy check the drill before

After drilling i go slowly and always checking the deep for the corby bolts

After i am happy i start cutting the scale close to the profile

And we get this

Then i clamp the scales together to fix the "bolster" area

After i am done i'm sanding to 1400 grit so it can be ready to glue.Otherwise if i glue it no sanding after

An idea of it

Now its time to glue it . First of all i have the handle in 80 grit and the scale.So it can be rough and the epoxy to stick much better.

Before adding the glue i clean them with acetone

And here we are I let it dry for 24 hours before start sanding it

I let it dry for 24 hours before start sanding it

And after is glued i start sanding it slowly with rough belt and cold water next to me so i wont over heat the epoxy.

And we get those results

Every comment and critism ideas are welcome!

Thank you for looking and if i am missing something plz free to ask

Vagelis

The steel i am using is O1 .

I start first with transfering the image to the steel.I used the spray glew to attach the print.

After using my angle grinder to cut as much steel as i could.

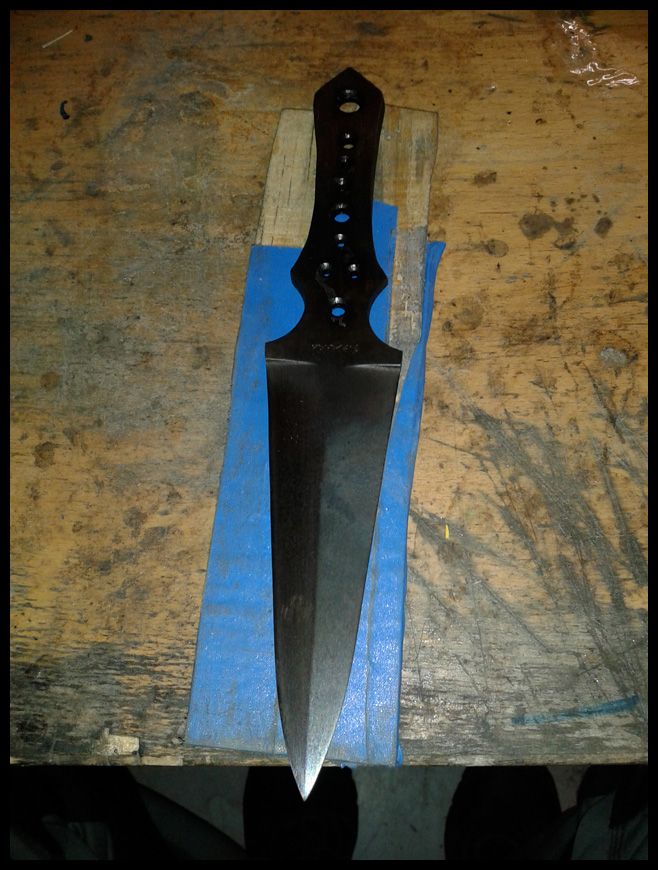

Then took it to the grinder and profiled it with a 40 grit belt and got this result

Before i drille the holes i attached the logo with the press but i forgot to take a picture of it.I did the main holes only so i can have an idea of the weight of it after the grinding

Now i was marking for the grind i used the tape to get the midle from the tip to the top .Did it for both sides.Hope that you understand what am i doing

After i did free grinding i got this result . I used 40 grit belt

Now its time for traditional hand rubbing before HT and also to make the lines straight when i get some time

Ok handrubbing before HT .I finished till 120 grit.And the reason was i was out of sand paper and i was bored waiting .Better to finish it to 320 grit.

Much easier after + ready for HT

[video=youtube;vXfIkI9aRa0]http://www.youtube.com/watch?v=vXfIkI9aRa0[/video]

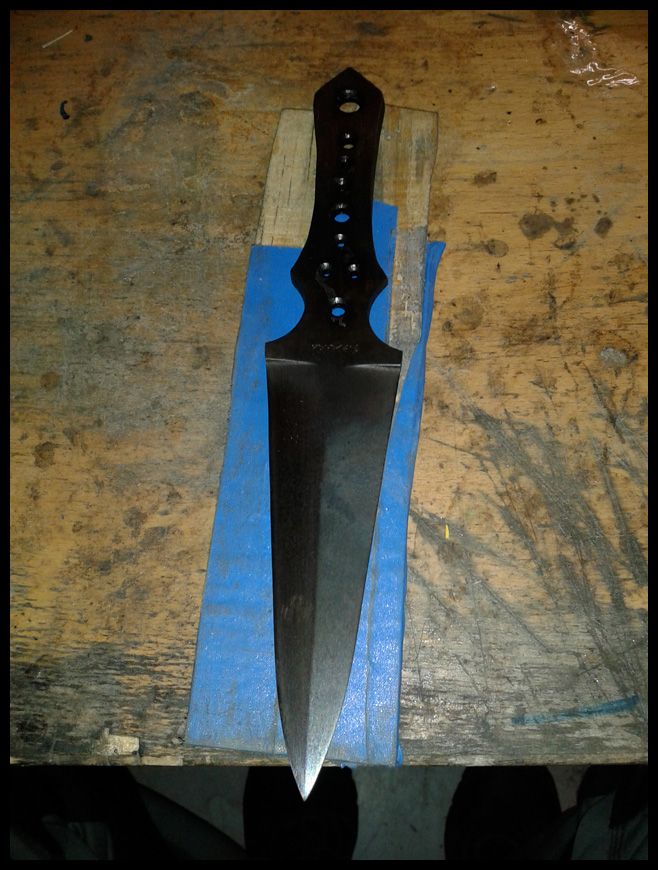

HT is done and here it is

Now hand rub again i start with 80 grit i find it easier for me and the lovely wd-40 and i finish to the point i want this is done 800 satin

After this we go to scale preparation I also sharpened the one side to test the hardening of it

Rapping with duck tape all the blade to avoid unpleasant scratches also before i tape it i usually clean it with cotton and aseton

Now i check if the scales are flat with the handle

After i am pleased i puting double side tape so i can stick the handle on mark the holes etc and profile draw the handle

AFter im done with this i take it to drill the holes,keeping the blade on the handle.

Of course i drill the corect sizw just a little bit , just to make the hole for the drill bit. Otherwise if i go all the way through ACCIDENTS might happen

As you i am using corby bolts

Also alwasy check the drill before

After drilling i go slowly and always checking the deep for the corby bolts

After i am happy i start cutting the scale close to the profile

And we get this

Then i clamp the scales together to fix the "bolster" area

After i am done i'm sanding to 1400 grit so it can be ready to glue.Otherwise if i glue it no sanding after

An idea of it

Now its time to glue it . First of all i have the handle in 80 grit and the scale.So it can be rough and the epoxy to stick much better.

Before adding the glue i clean them with acetone

And here we are

And after is glued i start sanding it slowly with rough belt and cold water next to me so i wont over heat the epoxy.

And we get those results

Every comment and critism ideas are welcome!

Thank you for looking and if i am missing something plz free to ask

Vagelis

Last edited: