Smallshop

KNIFE MAKER

Hey guys,

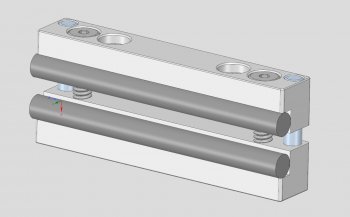

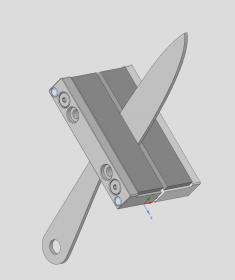

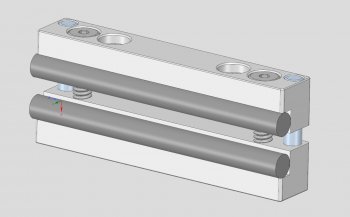

I'm thinking of making a file guide. After looking at some I think I don't want flat carbide inserts. I think precision ground carbide rod (silver soldered on to stainless body). I think a rod has a couple advantages....it gets behind the belt and does not exert any influence on the length-wise blade taper when you get close to the stop a flat could possibly be doing that. rods merely stop the blade . here's my design. It will handle a blade 2.0" wide. I can make it wider if need be.

Questions..comments...critiques all welcome.

I made a small aluminum one for my son when he was grinding his knife...it was good for that blade...barely. There's four of us making knives here...so I'm thinking of making four and don't want to make four of something to discover my ignorance has everyone in the shop looking at me sideways...:3:

I'm thinking of making a file guide. After looking at some I think I don't want flat carbide inserts. I think precision ground carbide rod (silver soldered on to stainless body). I think a rod has a couple advantages....it gets behind the belt and does not exert any influence on the length-wise blade taper when you get close to the stop a flat could possibly be doing that. rods merely stop the blade . here's my design. It will handle a blade 2.0" wide. I can make it wider if need be.

Questions..comments...critiques all welcome.

I made a small aluminum one for my son when he was grinding his knife...it was good for that blade...barely. There's four of us making knives here...so I'm thinking of making four and don't want to make four of something to discover my ignorance has everyone in the shop looking at me sideways...:3: