Randy,

No problem on the info in the WIP. Making blades is a process of learning that never ends for us all. Sharing info like this is a great way to spread info, spark interest, raise questions and answers, and give us all an oppertunity to learn something new.

I'm certainly still a student myself but being as detailed as possible allows me the oppertunity to learn, make mistakes, be corrected and continue to grow as a maker. (Many teachers will drop you a PM and offer advice and suggestions for improvement)

Since your's is the second comment about grinding post HT I'll share my thoughts on this and why I'm not worried about trouble grinding these hardened blades.

Hypothetically- lets say we've got 2 identical blades to grind, one 1084 and the other CPM M4 both hardened and tempered to 60 rockwell.

We pretty much know from others experience that the M4 is gonna trash belts, put hair on your chest, and make men out of boys. The 1084, no problem... beginners steel.

Now both blades are the same hardness so they should grind the same right ? WRONG and here's why- Carbides

1084 is a simple steel with just iron and carbon and will form iron carbides when the carbon bonds with the iron atoms. There aren't any other carbide forming elemnts in 1084.

Now lets look at the M4- Carbon, Chrome, Vanadium, tungsten, Molybdenum which will all form carbides. This is important- Not all carbides are created equal. I believe Vanadium carbides are the hardest and carbon carbides are the softest and the others fall in the middle. All these carbides are suspended throughout the iron which is why you can get a rockwell of 60 while maintaining the extreme hardness of those indivdual carbides. In a nutshell the Rockwell reading will tell you the hardness of the "matix" the carbide is suspended in NOT the hardness of an individual carbide.

Now as this applies to grinding it's those extremely hard carbides that wear out belts extra fast.

Now lets look at 52100's carbide forming elements 1% Carbon and 1.5% Chrome. The carbon will be no more of a problem than grinding 1084. At 1.5% we'll also have chrome carbides just not alot of them when compared to a typical stainless steel. I've never had an issue grinding ATS-34 after hardening so I'm not anticipating any roblems here.

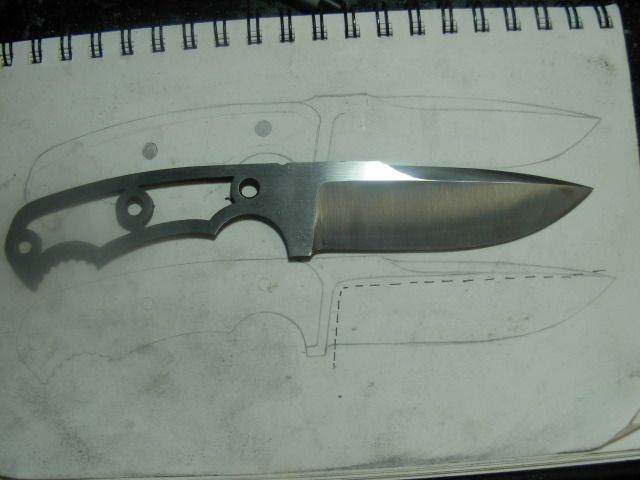

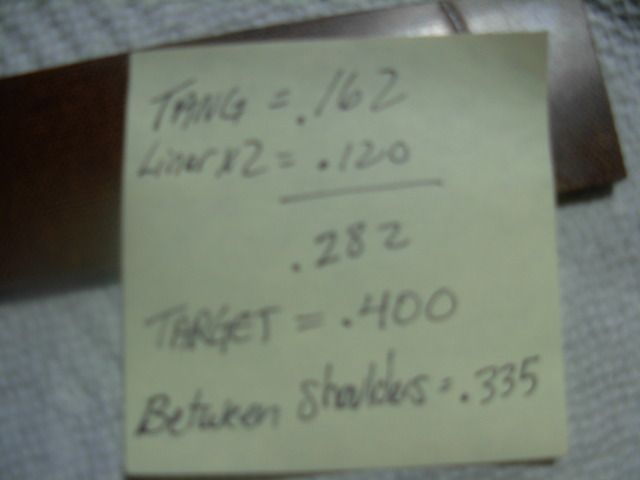

All this coupled with the fact that I gave these blades a soft (spring) back draw so the tang and upper portion of the blade is pretty soft in comparison to a typical blade hardness.

I'll report back after grinding these blades but my prediction is it won't be an issue at all.

Knowing when the time is right to retire a belt helps too

~It took me a looooong time to figure out that a worn out belt still has alot of texture too it and appears as though it'll still cut. And in fact it will still remove steel although requiring extreme pressure and with the added feature of building up extreme heat very fast~

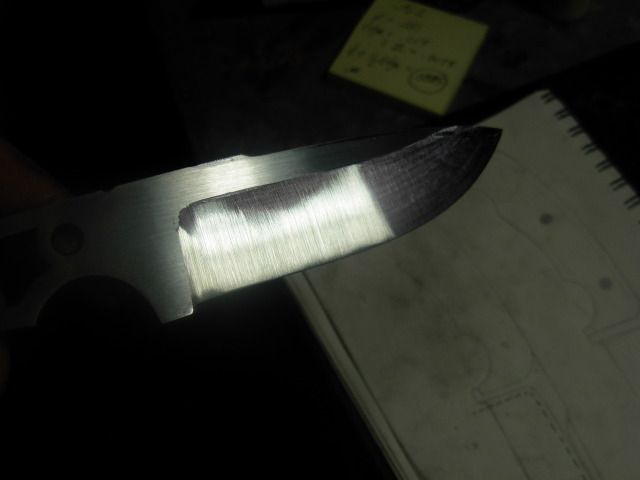

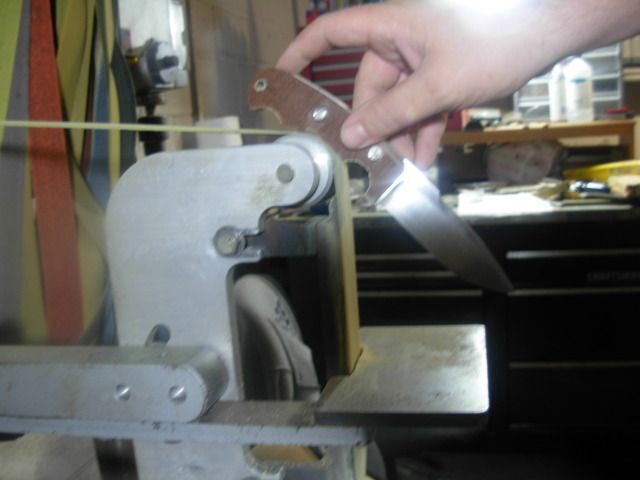

I think it's also worth mentioning while talking about grinding that as my skill and confidence in my grinding grew I can grind a blade MUCH closer to finished size with a rougher belt while finishing a small portion of the grinding with an 80 grit and using belts above 80 for finishing only. ( I define finish grinding like this- I'm not attempting to change the shape of the steel only refine the scratch pattern.

Thanks for the comments fellas- Josh