You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I Have a 40+ lbs Box of G-11 to Give Away, interested?

- Thread starter JatMat

- Start date

Sean Cochran

Well-Known Member

Jim, I cant thank you enough. You sent me a box big enough to keep me going for quite some time. Ive got an idea for some of it already, a two blade, linerless, toothpick fishing knife. Cant wait to get started on it, just got to finish what is on the bench. (have 5 going right now.)

Thanks again, and I would suggest anyone to contact Jim about some of this, it is great stuff.

Sean

Thanks again, and I would suggest anyone to contact Jim about some of this, it is great stuff.

Sean

D

DesignsbyDrew

Guest

G-11 Giveaway

Jim

Just joined today and saw your great offer. Yes please sign me up for a chance. Just started knifes a few years ago. Have the basics down, but am now working on fit and finish.

Jim

Just joined today and saw your great offer. Yes please sign me up for a chance. Just started knifes a few years ago. Have the basics down, but am now working on fit and finish.

HELLGAP

Dealer - Purveyor

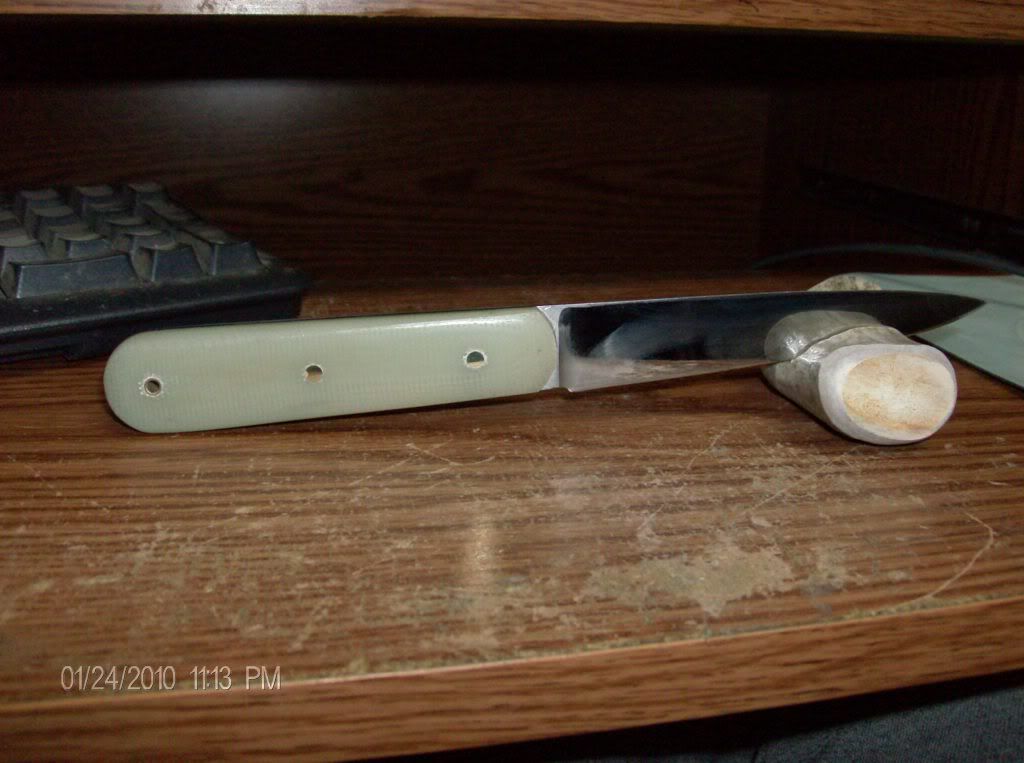

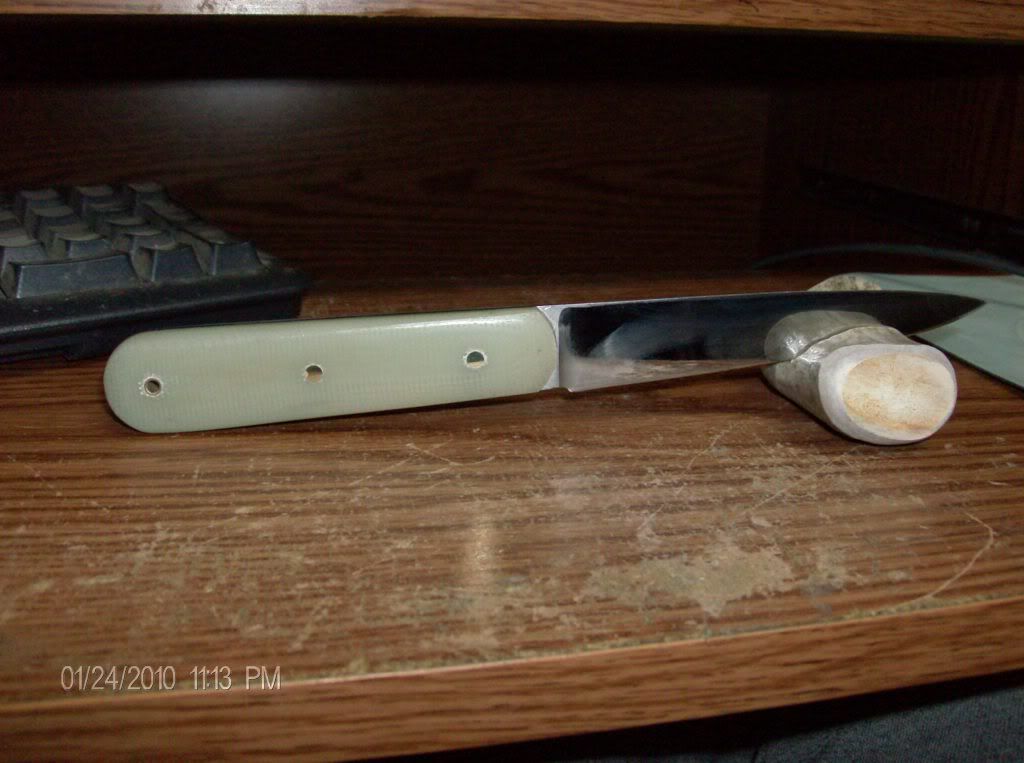

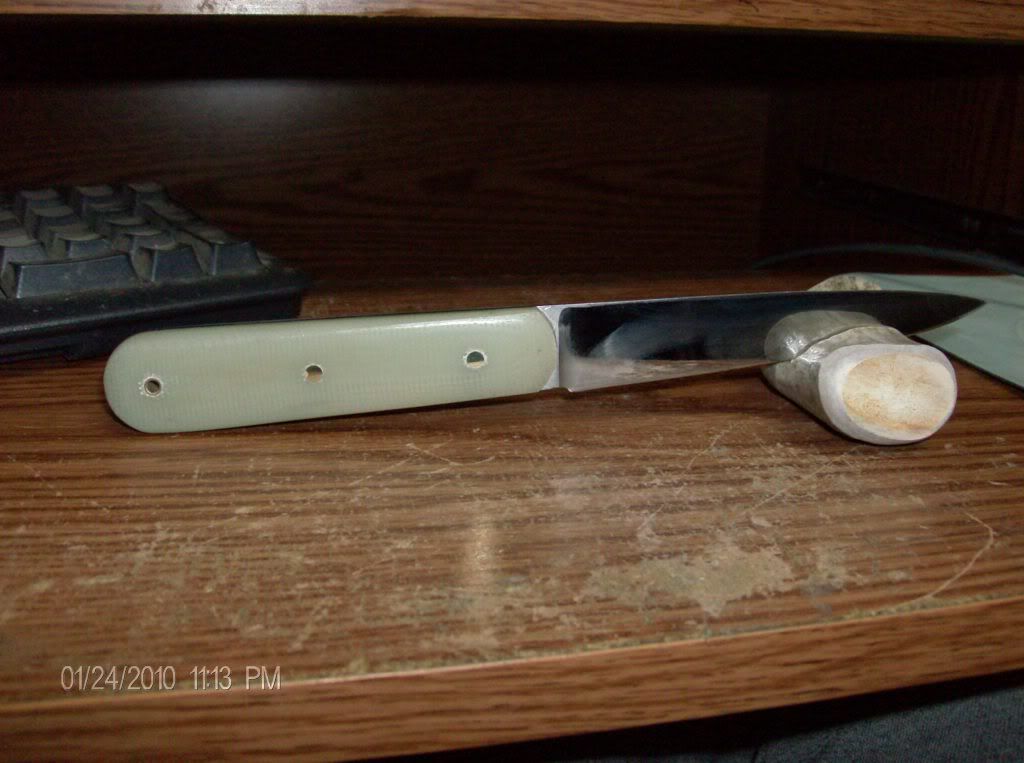

Jim here is one I just did well last week . Ide like to know if there is a better way to drill the holes so they dont chip being drilled after being glued on one side at a time doesnt work well . I will how ever get a 5/16 cobalt drill bit for the next attempt. this one is a little paring knife 1095 steel

JatMat

Well-Known Member

Jim here is one I just did well last week . Ide like to know if there is a better way to drill the holes so they dont chip being drilled after being glued on one side at a time doesnt work well . I will how ever get a 5/16 cobalt drill bit for the next attempt. this one is a little paring knife 1095 steel

Are you getting chipping on entrance end or exit end of the procedure? If on the exit end, predrill all the way through with a drill bit 1/2 the diameter of the hole you want then drill with the right size almost through from both sides. The first small drill all the way through should give you a good centering for the correct sized bit.

BTW: Nice paring knife,2thumbs

Jim

Recieved the box mid week but wasnt in town,.. Thumper told me it was here when I called home.

I asked about it and told her it was going to be heavy, she said, " Well, Sarah the mail lady was cussin you when she left it, so im betting this is it" LOL.

Thanks again, this should make some interesting things,as well as some cool scales.

Pix when I use it

I asked about it and told her it was going to be heavy, she said, " Well, Sarah the mail lady was cussin you when she left it, so im betting this is it" LOL.

Thanks again, this should make some interesting things,as well as some cool scales.

Pix when I use it

amcardon

Well-Known Member

Hey Jim, I'm trying to decide if I should use the G11 on knives or for bullet-proof armor! Good crap this stuff is tough! I was hoping I could cut it in half without a bandsaw but that's not gonna happen - but once I get somebody to cut it up for me, on steel it will go! Thanks again Jim!

Allen Newberry

newberry knives

I should have a couple of knives with G-11 to post up soon. Maye even tomorrow.