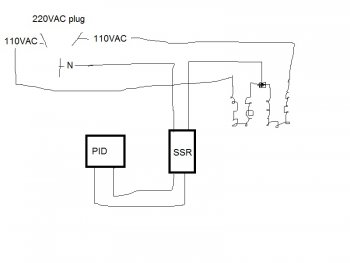

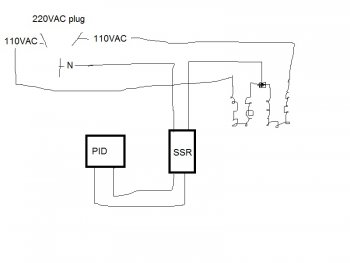

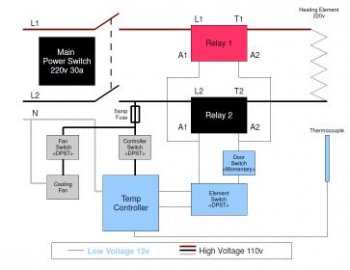

I'm building my own oven, did it before as a 110V unit and it worked ok. But I would like a quicker heat-up time and putting the oven itself together is not too difficult. Same with cutting the channels for the coils and the physical part of wiring the PID, SSR plug and a fuse. But to make sure everything will work on a USA 220VAC circuit can someone with more experience than I or some technical knowledge take a look at my very crude drawing and see if the final product will actually heat up without burning down the shop? Thanks.