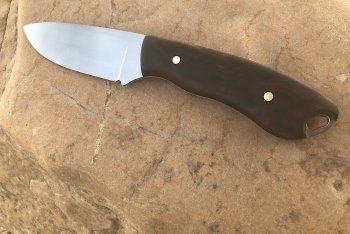

Dennis Morland

KNIFE MAKER

That is going to be a handy knife...

Nope...That's the way I like to do it. I think on smaller knives it's easier....don't know if it would be for a bowie, etc...Thank you for the comments. My plan at this point is to mark out and grind in the tang taper, and remove a little weight that way. Then I’m planning on marking out the grind line I’d like and do my absolute best to stick to that. I have a bad habit of “letting the steel tell me what it wants to be”. Well, more my grinder telling the steel what to be.

Along those same lines, I’m going to leave plenty of material pre-heat treat and then work to the desired shape post heat treat. Anyone ever have any issues doing it that way?

nice classic profile.

I noticed you put your sharpening notch in before grinding. I've never done that myself as I usually have to chase matching up the plunges a little. Once I have them matched, I put in the notch, often after hardening with a carbide rotary tool.