EnviroDaren

Active Member

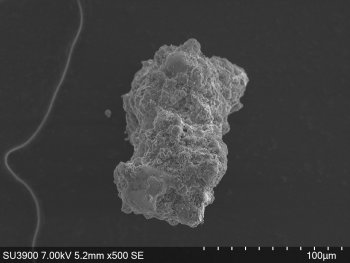

My company produces abrasive powders for industrial polishing applications and one of my goals is to determine the best format for this material as a product for polishing knives. Here's a link to one of the powders we make, called Mg-35. Our latest focus is on synthetic spinel powder/diamond, which is similar to Mg-35, but much harder and more abrasive.

Would a dry powder be ok or do knife makers prefer the abrasive in a liquid suspension or a cream? The powder is very dusty and becomes airborne easily, so using it dry requires a dust mask.

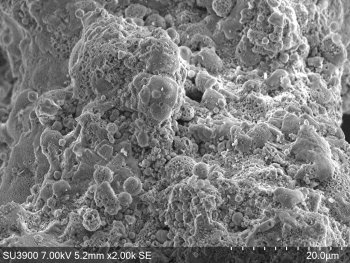

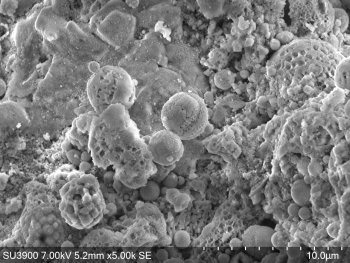

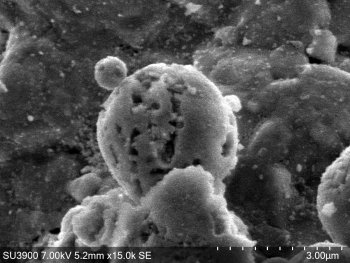

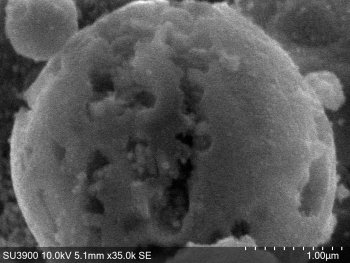

The material is a ceramic powder with diamond fused into the particles. As it is being used, the larger particles break down, which enables polishing from a coarse surface finish to a mirror-like appearance in one step.

I can send a few samples out to anyone interested in evaluating it. Thanks!!

Would a dry powder be ok or do knife makers prefer the abrasive in a liquid suspension or a cream? The powder is very dusty and becomes airborne easily, so using it dry requires a dust mask.

The material is a ceramic powder with diamond fused into the particles. As it is being used, the larger particles break down, which enables polishing from a coarse surface finish to a mirror-like appearance in one step.

I can send a few samples out to anyone interested in evaluating it. Thanks!!