Entropy762

Well-Known Member

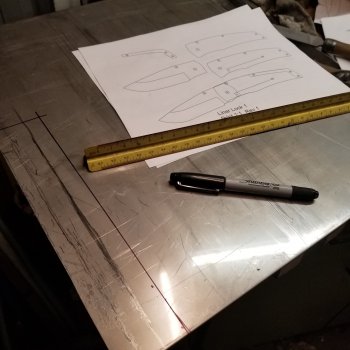

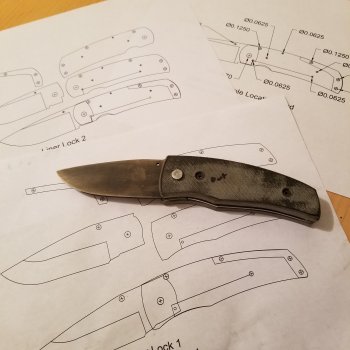

I've started on my second liner lock. This time I will concentrate on my process. The liners are going to be stainless steel and the blade will be 1095. I also procured some 1/16" ball bearings to use for the detent. Dang those things are small.

Jake

Jake