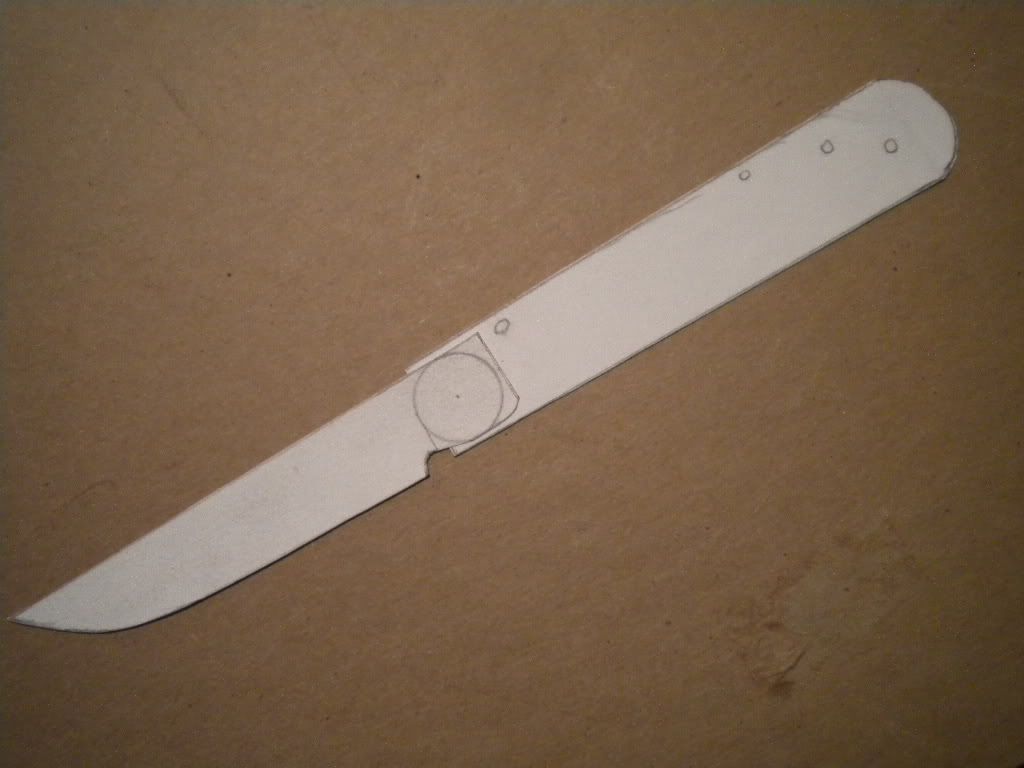

Not that I don't have alot of other irons in the fire, but I've been wanting to make a liner lock folder. The wife's been gone for the past couple days and the kids have been with me, so no garage time, but lots of craft time  while the girls cut up straws and paper to glue together I decided to draw up a pattern for a folder. I'm loosely following Ray Roger's tutorial ( http://www.rayrogers.com/ftutorial.htm ) Here's the pattern

while the girls cut up straws and paper to glue together I decided to draw up a pattern for a folder. I'm loosely following Ray Roger's tutorial ( http://www.rayrogers.com/ftutorial.htm ) Here's the pattern

I'm attempting to get the look of a small tanto when open, I'm going to try for a hamon and cast some Shibuichi for the bolsters. I've cast my fair share of bronze and aluminum so I'm gonna try to alloy some silver and copper

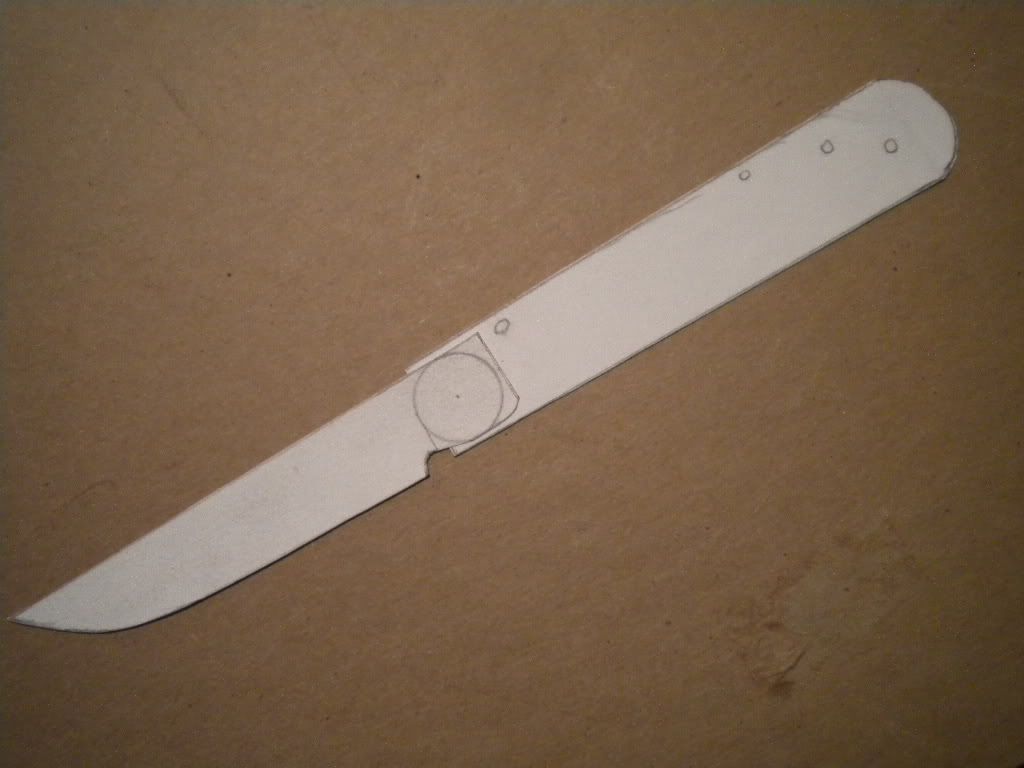

Tonight when my wife got home, she let me out in the garage for a little bit, so I dug out some 1/2" round W1 and forged it to rough shape. I'm a better machinist than blacksmith (for now, I'm still practicing) so I decided to forge it oversize without bevels and then mill it to thickness so as to get a good uniform straight blade. I'll then cut the blade out from the steel, and then grind the bevels in after making the rest of the knife. Here's the forged and milled chunk of W1

That's about all I have so far, let's hope I can keep my attention focused on this long enough to get it done.

Thanks all for watching, comments and critisizm are both welcomed

Zeb

I'm attempting to get the look of a small tanto when open, I'm going to try for a hamon and cast some Shibuichi for the bolsters. I've cast my fair share of bronze and aluminum so I'm gonna try to alloy some silver and copper

Tonight when my wife got home, she let me out in the garage for a little bit, so I dug out some 1/2" round W1 and forged it to rough shape. I'm a better machinist than blacksmith (for now, I'm still practicing) so I decided to forge it oversize without bevels and then mill it to thickness so as to get a good uniform straight blade. I'll then cut the blade out from the steel, and then grind the bevels in after making the rest of the knife. Here's the forged and milled chunk of W1

That's about all I have so far, let's hope I can keep my attention focused on this long enough to get it done.

Thanks all for watching, comments and critisizm are both welcomed

Zeb