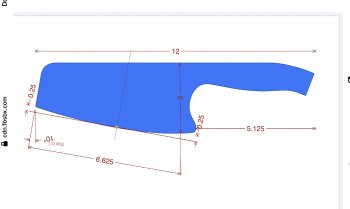

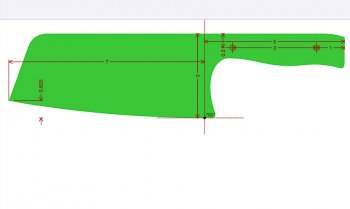

YUP!! All those lines and numbers!!

Honestly, I've had a number of people over the years send similar things when ordering a knife, and I've even had a couple send actual Blueprints (the blueprints I simple returned and told the clients I don't build knives in that manner) All were complete train wrecks to me, because although it all looks good on paper, in my experience it almost never comes out as intended. It's very likely just the way I build knives in that I don't draw out anything, expect folders. I've found that trying to build to exact specs of a client/customer often produces a knife that looks OK, but handles and performs awful. In that particular design/drawing, there are a few things that scream out to me. I've also found that it's usually exasperating to try to talk a client out of things/features that I know they are not going to like, so If I build a knife they have draw to specs, it is understood that there are not refunds/returns, and more times then not, I get that call anyway, after they've tried to use the knife a time or two and found they don't like something about it. Sometimes they will order another knife, but this time they will just tell me what they want to use it for....and let me build it, which to date, has always worked out well.

I suppose it's easier for me then some, just because of all the years dealing with/building knives.