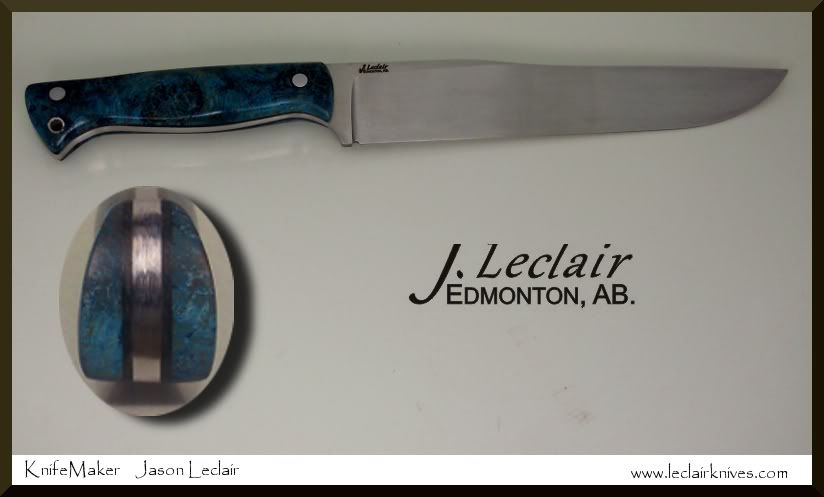

J.Leclair

Well-Known Member

Hey all, A guy I work with asked me to make him a bowie knife. I figgured I'd do a WIP.

he wanted an 8" blade and a 4.5" handle. I started with a 3/16" X 1.5" piece of 440C and got the profile ground. didnt want to spend too much time in the shop tonight as it is valentines day and all.... good thing my wife loves me

here's where I'm at so far

will work on the bevels tomorow

he wanted an 8" blade and a 4.5" handle. I started with a 3/16" X 1.5" piece of 440C and got the profile ground. didnt want to spend too much time in the shop tonight as it is valentines day and all.... good thing my wife loves me

here's where I'm at so far

will work on the bevels tomorow