kevin - the professor

Well-Known Member

Hello Everyone,

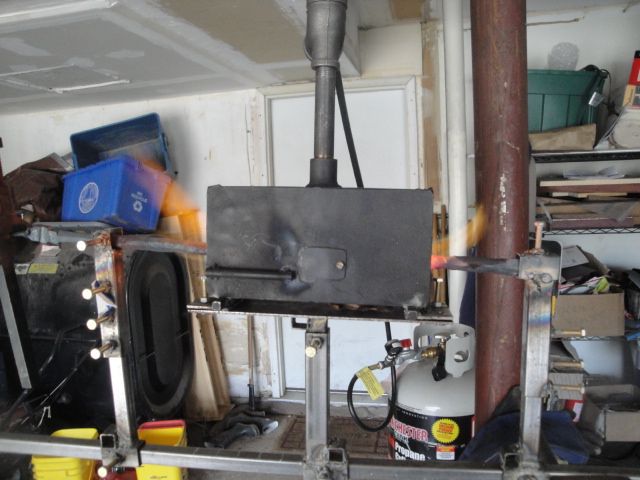

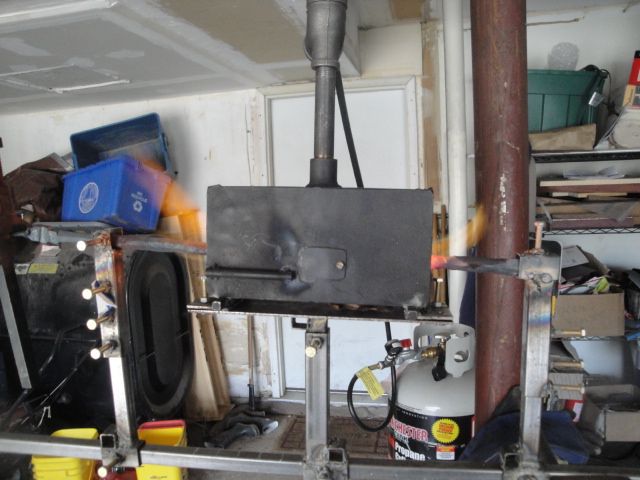

I just finished this one. I made myself a forge/twisting machine thingy (Twist-o-matic 3000) and I wanted to test it. So, I needed to do a multi-bar construction.

I also wanted to play with 80crv2, o1, and 15n20. These steels are a lot tougher and more abrasive resistant than the 1075 I often use. Nothing against Aldo's 1075 (it is the perfect simple steel). But, I wanted to play with other alloys.

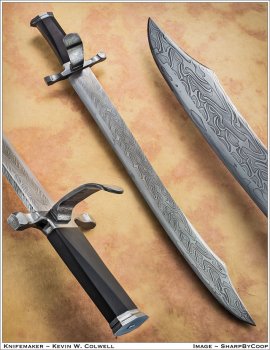

Blade is 18.5", and about 1.7" at widest point. The handle is almost 5", a tad more if you count the guard portion where your hand can sit.

Everything is pattern welded. The fittings are 1084 and 15n20.

Handle is ebony.

thanks for looking.

comments are welcomed. (there are a ton of pics of the whole process here:

http://s579.photobucket.com/user/thor2888/library/4-bar grosse messer wip?sort=3&page=1

Kevin

I just finished this one. I made myself a forge/twisting machine thingy (Twist-o-matic 3000) and I wanted to test it. So, I needed to do a multi-bar construction.

I also wanted to play with 80crv2, o1, and 15n20. These steels are a lot tougher and more abrasive resistant than the 1075 I often use. Nothing against Aldo's 1075 (it is the perfect simple steel). But, I wanted to play with other alloys.

Blade is 18.5", and about 1.7" at widest point. The handle is almost 5", a tad more if you count the guard portion where your hand can sit.

Everything is pattern welded. The fittings are 1084 and 15n20.

Handle is ebony.

thanks for looking.

comments are welcomed. (there are a ton of pics of the whole process here:

http://s579.photobucket.com/user/thor2888/library/4-bar grosse messer wip?sort=3&page=1

Kevin