You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

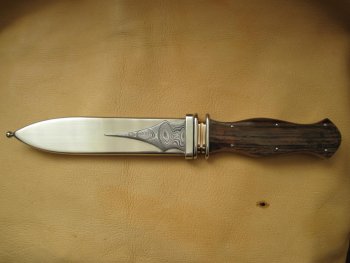

Problem knife

- Thread starter oldknife

- Start date

rhinoknives

Well-Known Member

HELLGAP

Dealer - Purveyor

Mammoth ivory is one I have but I am to afraid to use because it splits and cracks under heat stress from sanding .You make outstanding knives and the sheath is to die for way more tallent than me . Guys like ed caffrey , fred rowe or some of the other masters can help you .Sorry I cant help you. kellyw

Mark Behnke

Well-Known Member

Nice package, how do you finish the inside of the sheath? I did one but it is a loose fit with no lining, thought of making a snug fit at the ricasso but concerned about scratches.

Thanks Mark

Thanks Mark

Bruce Bump

Forum Owner-Moderator

Nice dagger.

Why did you have to remove the handle?

I'm not familiar with 308 steel. is that a stainless steel?

Why did you have to remove the handle?

I'm not familiar with 308 steel. is that a stainless steel?

Hellgap, thanks for the kind comments, on the mammoth use sharp belts slow your grinder down, I don't go any finer than 220 belt, finish from there by hand. Mark thanks for the comments, I put scotch tape on the blade so it is protected from scratches, super glue a piece of micarta the full length of your formed halves so you can hang on to it and it will keep it from warping from the heat from grinding, cut out a set of liner material that you are going to use and fit the sheath to the blade, use new liners to finish, these will have grit in them hopefully it will hold it't shape when soldered. I line my sheathes all the way to the bottom, use two pieces on the sides and two for the flats, i use an old thin machinist rule that have done some grinding on do the sides first, use double stick tape to put the rule on the liner use contact cement don't let it dry and slide your pieces in, it takes a day or two for the glue to dry. If it all goes to pot fill it with lacquer thinner and start over, hope this helps. Deane

Bruce, had the knife covered with tape when I put it to gather the handle frame had a little side slop in it and did not line up with the blade, did not see it until I pulled the tape. Buzz tell's me that 308 is a boiler plate, I am not a blade smith so believe everything he tells me, I put it in etch was not doing much so gave it back to him, he soaked it overnight two times to get it where it is now, whatever it is one tough blade. Deane