You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

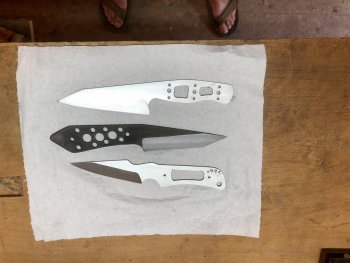

Proud enough to share pictures.

- Thread starter SS369

- Start date

Gene Kimmi

KNIFE MAKER

Those look really good! Great job!

SS369

Well-Known Member

Thank you Gliden.

One is my first full term knife. I have practiced on many afterward, before the second picture, using various materials, ie., thin plywood, MDF, G10 and steel from the box store.

None of which has the same feel as good steel.

BTW, both of these were ground and worked post heat treating (except profiling and holes) and that was a real eyeopener. I was so worried about ruining the temper.

I had no idea that the hand sanding would be so,,, laborious.

One is my first full term knife. I have practiced on many afterward, before the second picture, using various materials, ie., thin plywood, MDF, G10 and steel from the box store.

None of which has the same feel as good steel.

BTW, both of these were ground and worked post heat treating (except profiling and holes) and that was a real eyeopener. I was so worried about ruining the temper.

I had no idea that the hand sanding would be so,,, laborious.

Daniel Macina

Well-Known Member

Something to be proud of for sure! Great job!

Brett Schaller

Well-Known Member

Really like the design on the second one (not that there's anything wrong with the first one . . .  )

)

SS369

Well-Known Member

Ktip

Steel AEB-L .110 HRC 61-62

OAL 9 7/8"

Cutting edge 5 7/8

Handle stabilised Box Elder dyed burl with TruOil

Brass Corby bolts and GFlex

.010 behind edge @ 18 degrees

Finished to 400 grit

Steel AEB-L .110 HRC 61-62

OAL 9 7/8"

Cutting edge 5 7/8

Handle stabilised Box Elder dyed burl with TruOil

Brass Corby bolts and GFlex

.010 behind edge @ 18 degrees

Finished to 400 grit

Attachments

Dennis Morland

KNIFE MAKER

I had no idea that the hand sanding would be so,,, laborious.

Check out Red line sandpaper. Really makes a difference. Just use it once and you will be hooked. It is that good.

Check out Red line sandpaper. Really makes a difference. Just use it once and you will be hooked. It is that good.

SS369

Well-Known Member

I had no idea that the hand sanding would be so,,, laborious.

Check out Red line sandpaper. Really makes a difference. Just use it once and you will be hooked. It is that good.

Oh yes Dennis, hand sanding is a mess. One little hesitation and .... Again.

I do use Rhynowet paper and a backer with either WD40 or Windex as wetting agent.

Bruce McLeish

Well-Known Member

much better!Had a challenge...

Should be showing now.

Randy Lucius

Well-Known Member

Very nice! I really like the multi-colored scales on that second one. You're making some fine knives. Keep up the good work!Been a bit, but got to play some .

,125 AEB-L @ 61 HRC

Sean Jones

Well-Known Member

Very nice!

SS369

Well-Known Member

Very nice! I really like the multi-colored scales on that second one. You're making some fine knives. Keep up the good work!

Thank you all!

Randy, I really liked working those scale. Not super hard, so they sanded well and easy with no burn. I’m finding open coated 60 grit belts for the roughing to be best for me. Two thin coats of TruOil brought out the colors.

I am really liking AEB-L.

Doug Lester

Well-Known Member

Love the kiridashi, a first rate job.

Doug

Doug